The term plastic extrusion refers to a manufacturing process in which plastic items are made. This method involves pushing soft hot plastic material through a die or mold forcing it to take the shape of the die. Plastic is found everywhere in today’s products and goods and is used more and more every day. Because of this is it important that manufacturers use the best and most efficient process when creating products that are made out of plastic. Some of the many plastic molding processes include, blow molding, plastic extrusion, injection molding, thermoforming, rotational molding, and many more. Each of these methods caters best to a specific type of product making. Blow molding for example is the most common method that is used when creating plastic bottles or containers that are made to hold contents. Heat is used to form plastic in almost every process because it makes the material soft and bendable. I am sure that most of us have melted a plastic container in the dishwasher due to the plastic getting too hot and starting to take another shape. This is the perfect example of how plastic items are made.

Plastic extrusion is a process that is the best for making long continuous profiles at one time. Items like trim, siding, and floor strips are always long and being able to be made in such great lengths is perfect to create them. This process is also used to create items like drinking straws and pipes as they can be produced in a continuous form and simply be cut to size afterwards. Doing it this way increases the amount of production that is made in shorter length items at a time. It is much easier to cut through the plastic then top the die every five seconds or so. This method will continue to be used as a platform in the plastic molding industry for years to come.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

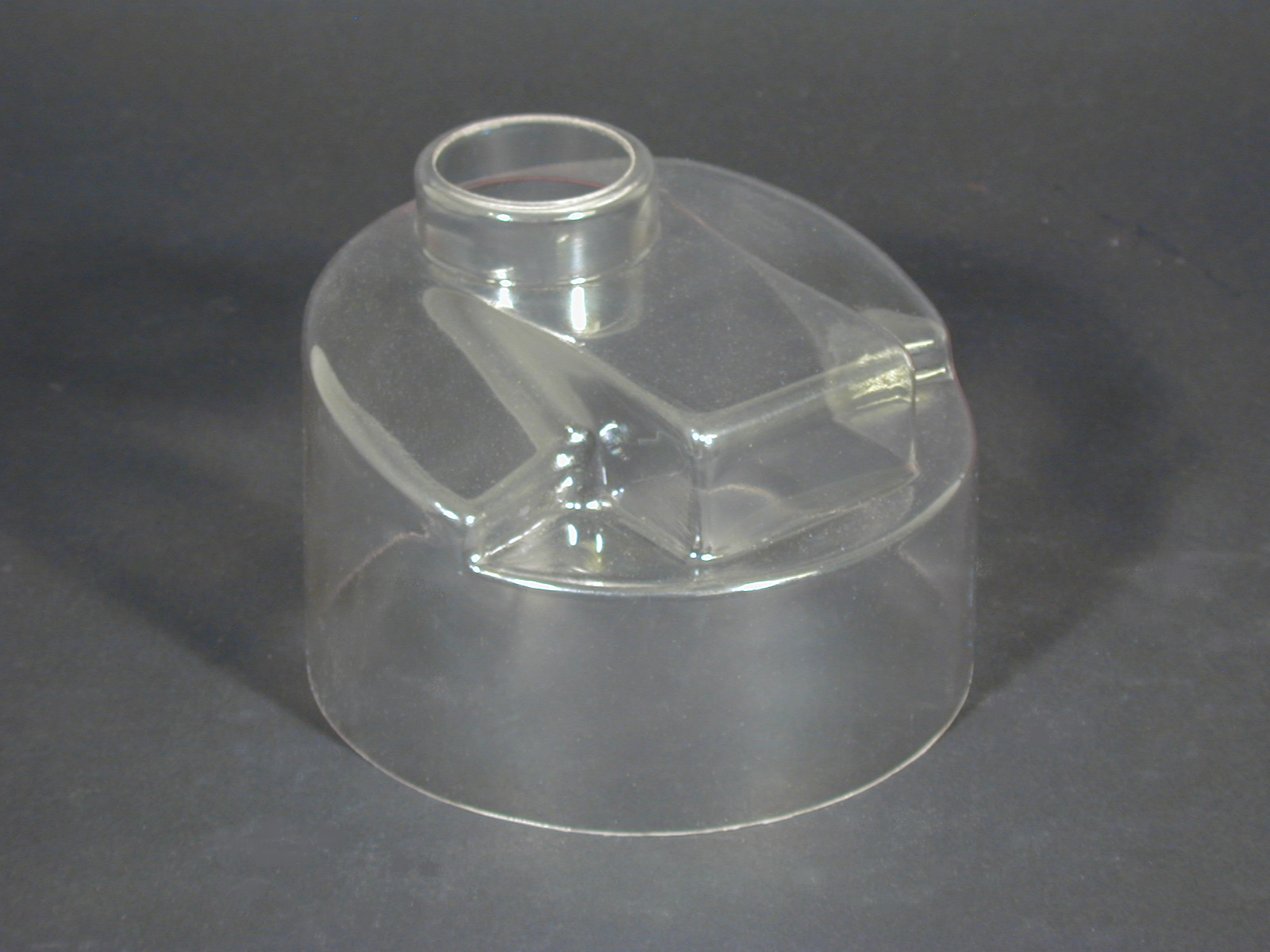

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

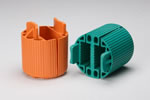

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services