PVC (Polyvinyl Chloride) extrusion is a high-volume manufacturing process used to form continuous profiles by melting raw PVC plastic. PVC is the most commonly extruded rigid plastic. It is cheap, exhibits recyclable properties, and is versatile for use in both indoor and outdoor environments. Read More…

Preferred Plastics, Inc. open_in_new

Location: Plainwell, MI

Preferred Plastics is an ISO 9001:2000-certified custom plastic extruder, specializing in rigid, flexible & co-extruded products, including extruded tubing.

FABEXCO open_in_new

Location: Modesto, CA

Our profile extrusion capabilities are vast and adaptable to meet your specific needs. Whether you require rigid, flexible, dual, or tri-profile extrusions, we have the expertise and technology to deliver. We are dedicated to pushing the boundaries of what's possible in plastic extrusion, and we welcome the opportunity to tackle even the most challenging projects.

Absolute Custom Extrusions, Inc. open_in_new

Location: Milwaukee, WI

We have a long history of providing plastic extrusions. We will proudly serve you and we are committed to quality customer service. Our plastic extrusions are used in industries ranging from automotive to medical.

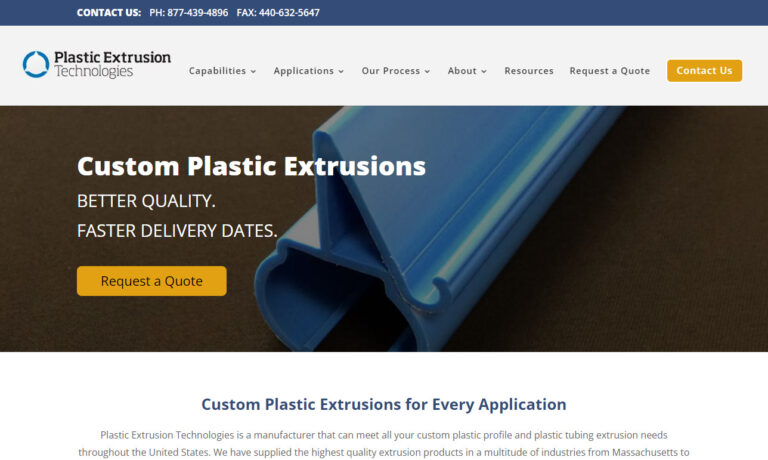

Plastic Extrusion Technologies open_in_new

Location: Middlefield, OH

At Plastic Extrusion Technologies, we specialize in the production of extruded plastics, catering to both large-scale manufacturing needs and smaller custom projects, all tailored to your precise specifications. We understand the importance of high-quality products, prompt delivery, and responsive service in today's fast-paced business landscape, and we are committed to meeting these expectations.

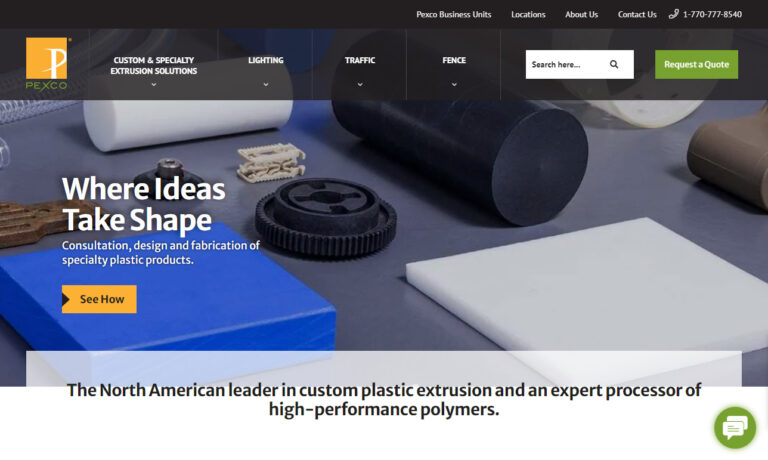

Pexco open_in_new

Location: Johns Creek, GA

As our name suggests, we are a leading custom extruder of plastic shrink tubing, flexible and rigid tubing, and profiles in standard or custom colors in a multitude of material options. We use state-of-the-art machinery for our extrusions and perform secondary operations on site, such as drilling, slotting, notching, etc. Pexco is ISO 9001 certified.

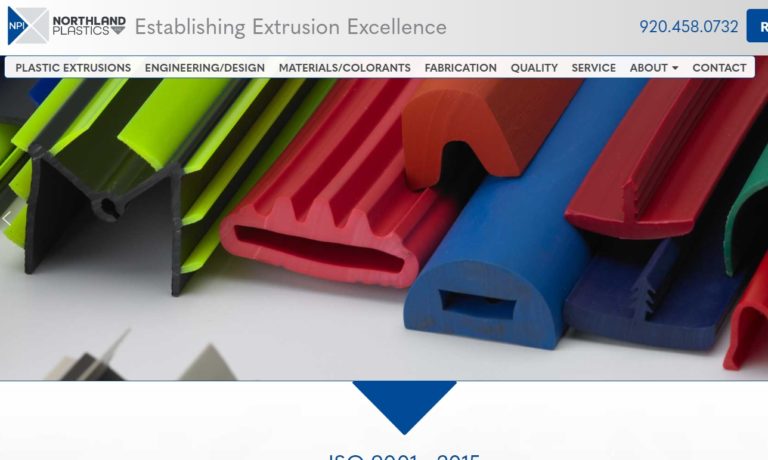

Northland Plastics, Inc. open_in_new

Location: Sheboygan, WI

At Northland Plastics, we are the experts in unique custom plastic extrusions. We specialize in single and dual durometer profile extrusions, vacuum calibration, automated inline fabrication, custom fabrication, and more. Custom colors and various additives are also available. As an ISO 9001:2015 company, we value product quality, timely delivery, competitive pricing, and excellent customer...

Petro Extrusion Technologies, Inc. open_in_new

Location: Middlesex, NJ

Petro specializes in plastic extrusions, offering our customers many capabilities, such as customized shapes & extruded tubing, along with tape application, coiling & angle cutting.

Polytec Plastics, Inc. open_in_new

Location: St. Charles, IL

We develop the most affordable and long lasting plastic extrusions. These extruded materials come in a variety of options and are Polytec Q-1 certified. We offer fast delivery and our customer service team is willing to design a perfect solution for your industry.

Keller Products open_in_new

Location: Manchester, NH

Since our founding more than 55 years ago, we at Keller have been the most innovative thinkers in the plastic profile extrusion industry. Our continued investment in new technology continues to pay off for our company and our customers; we are able to offer programs that eliminate tooling costs, we offer stocking and inventory programs and we can provide concept to tooling in less than five days.

GSH Industries, Inc. open_in_new

Location: Cleveland, OH

A plastic extrusion manufacturer of extruded plastic products, GSH Industries manufactures custom plastic extrusion profiles. We have continually expanded & attained our position as a preferred supplier of quality products & engineering ingenuity.

More PVC Extrusion Manufacturers

Consequently, rigid PVC extrusions are a popular choice for various applications. PVC is a hard polymer that can be further enhanced using impact modifiers. Extrusions made from rigid PVC exhibit strong chemical resilience, meaning that rigid PVC tubing can be easily welded, glued, and fused. This is ideal for joints in pipes. Extruded rigid PVC profiles, trims, and sections are more suitable for outdoor environments due to their high corrosion resistance. PVC also exhibits good insulation properties for use involving low voltage electric current. Due to the multiple benefits of rigid PVC extrusions, it has been used with success in both outdoor and indoor locations.

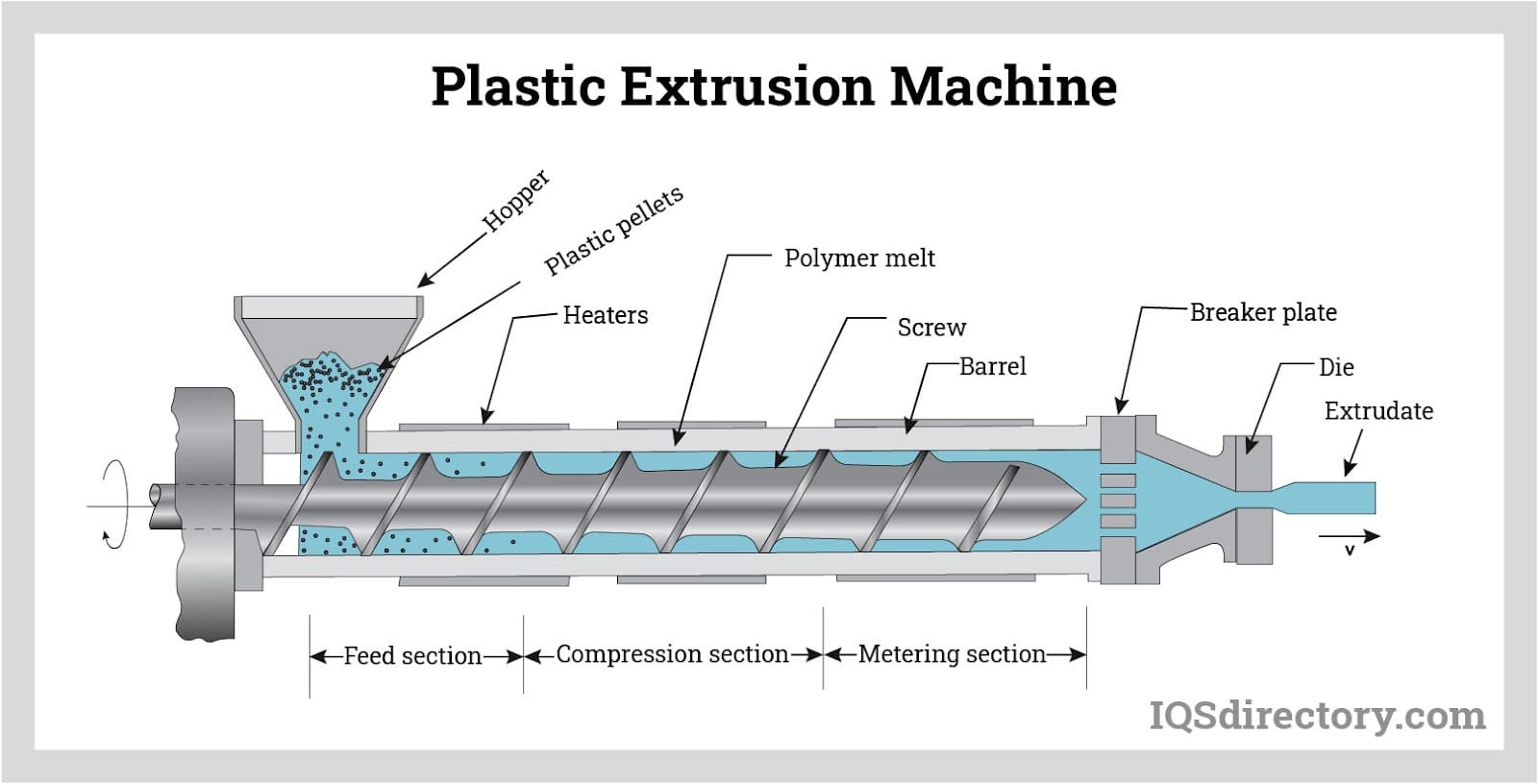

How PVC Extrusions are Made

PVC extrusions are made by the extrusion of PVC in raw material form. They generally follow the same procedure as typical pipe extrusion operations. The raw material pellets or powder are fed into the PVC twin screw extruder. The materials are then melted in multiple extruder zones. A die is used in the extrusion process to shape the extruded PVC into the desired product, for example, a pipe. The product is then cooled. In the case of pipes, they are then cut into the desired lengths. The materials are then melted in multiple extruder zones. A die is used in the extrusion process to shape the extruded PVC into the desired product, for example a pipe. The product is then cooled. In the case of pipes, they are then cut into the desired lengths.

Types of PVC Extrusions

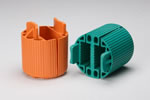

The different types of PVC extrusions include:

Flexible PVC Extrusions

Flexible PVC is softer and more amenable to bending than rigid PVC due to the use of plasticizers. Flexible PVC is mostly utilized to create electrical wire insulation. Many residential and commercial builders also use it to create flooring.

Rigid PVC Extrusions

Rigid PVC is the most commonly used form of PVC. It is strong, lightweight, and integral to numerous applications in the construction industry. PVC extrusions are easy to weld through the use of thermoplastic welding equipment. PVC extrusions are mostly used in construction, automotive, and marine applications. Common applications of PVC extrusions include parts to manufacture large doors, decking pieces, automobiles, and boats.

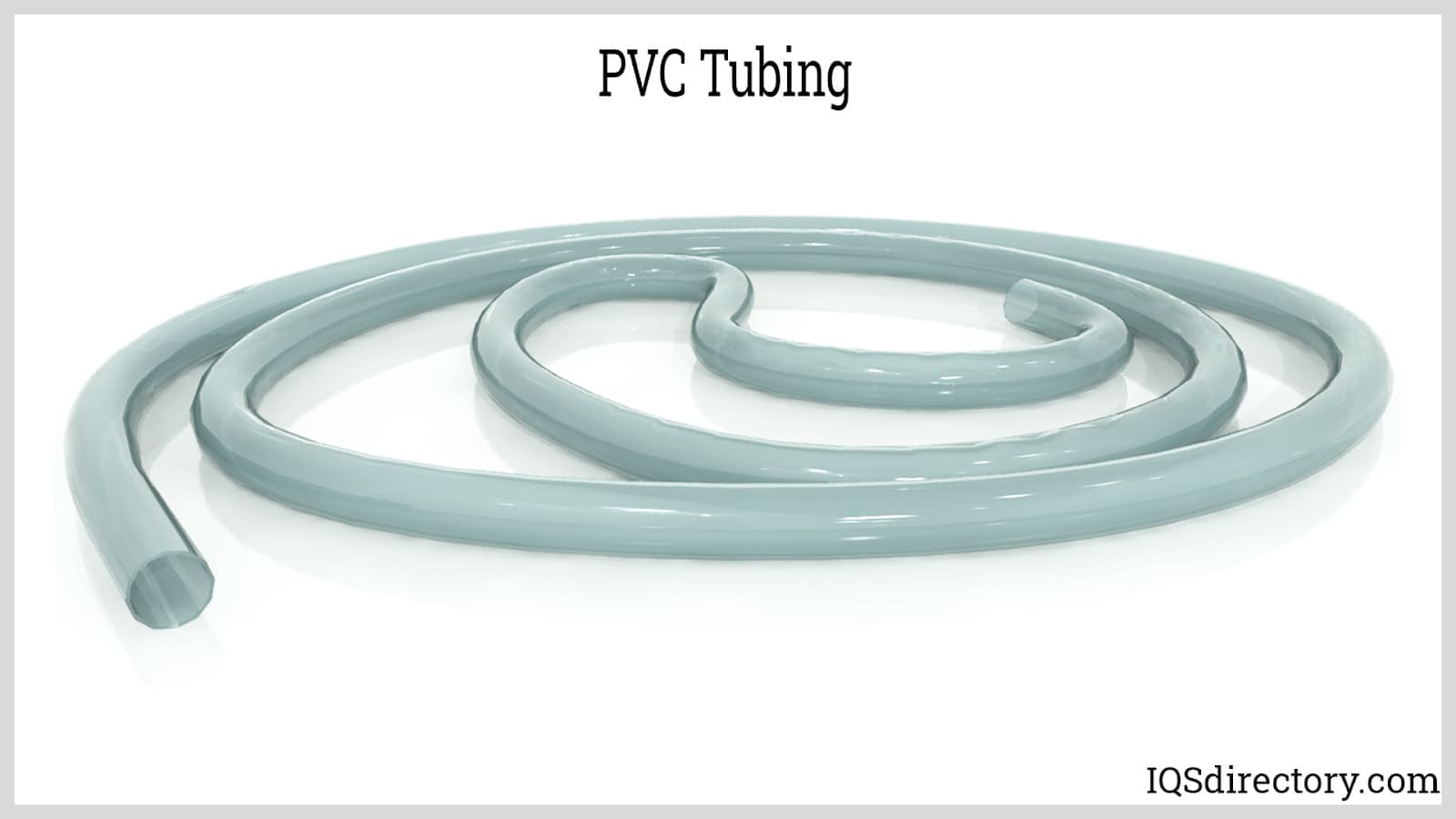

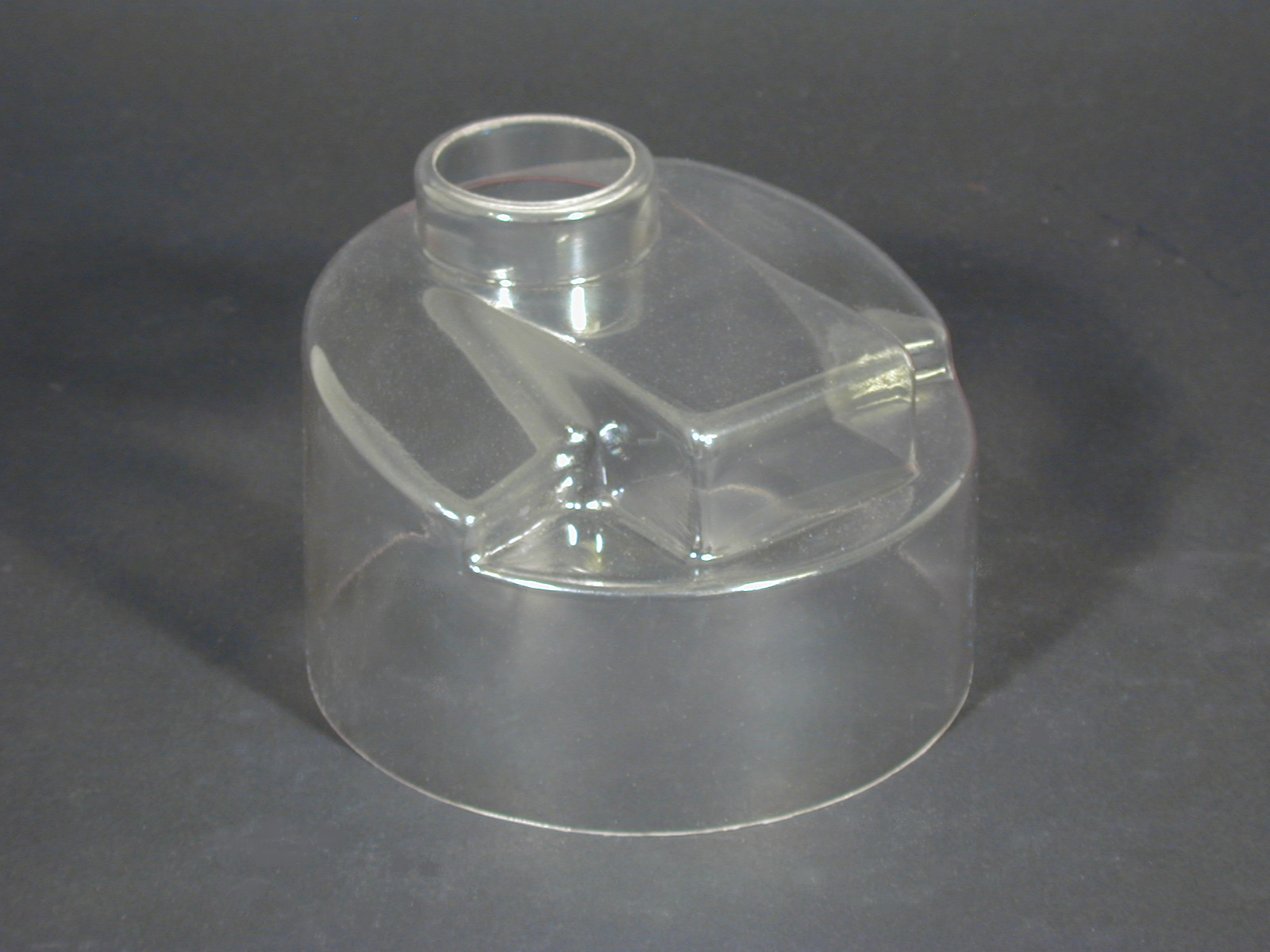

Plastic Tubing

Most plastic tubing is made from PVC material through the extrusion process. These PVC extrusions are extremely resistant to chemicals and corrosion and exceptionally flexible. There are different types of plastic tubing, including square plastic tubing.

Applications of PVC Extrusions

- Rigid PVC extrusions are widely used in the construction industry for water pipes, cladding, gutters, conservatories, window frames, and wall and door protection due to the excellent thermal properties and stability of rigid PVC.

- PVC extrusions are externally used in transport applications for caravans, boating, and vehicle bodies and internally for creating pleasing aesthetics (it is available in many colors and surface finishes).

- PVC extrusions are also used in the retail sector for point of displays, ticket strips, poster grippers, and storage racks.

Benefits of PVC Extrusions

The benefits of PVC extrusions include:

High Speed, High Volume, Low Cost

PVC extrusions allow for producing high volumes of parts quickly and at a low cost. The extrusion process is fast and efficient in producing continuous shapes with varying lengths. Products can be manufactured in high volumes, and wastage is minimal. The extrusion process eliminates tooling costs which makes it more efficient and timely.

Versatility and Variety

The process of PVC extrusion is highly versatile. It presents all sorts of opportunities to be creative. Products with complex shapes and varying hardness, thicknesses, colors, sizes, and textures can be created.

Alterations

PVC extrusions remain hot after the process of extrusion. This allows them to change shape to produce the desired shape.

Customization

Complex shapes with varying thicknesses, colors, and textures can be produced. With sophisticated machinery, a wide range of sizes and shapes can be possible. Moreover, additives make it possible to improve the product's durability, fire resistance, and positive properties and reduce friction, ensuring full product optimization to perform its function.

Disadvantages of PVC Extrusions

Because of the nature of PVC plastic, PVC extruders suffer a lot of friction and stress. This means that to guarantee long service life, PVC extrusion production lines require specialized extruders. These are extruders that use a twin-screw extruder configuration and also feature robust construction materials that can withstand the PVC extruder's harsh operating conditions.

Choosing the Correct Proper PVC Extrusion Manufacturer

To ensure you have the most productive outcome when purchasing PVC extrusions from a PVC extrusion manufacturer, it is important to compare several companies using our directory of PVC extrusion manufacturers. Each PVC extrusion manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or request a quote. Review each PVC extrusion business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple PVC extrusion companies with the same form.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services