Plastic extruders are versatile machines that are commonly used in the plastics manufacturing industry to produce a wide range of plastic products. These machines operate by melting plastic pellets or granules and forcing them through a die to create a continuous stream of plastic material in a specific shape or size. In this article, we will explore the various components of plastic extruders, the design variations, considerations regarding, and benefits and applications of plastic extruders. Read More…

Preferred Plastics, Inc. open_in_new

Location: Plainwell, MI

Preferred Plastics is an ISO 9001:2000-certified custom plastic extruder, specializing in rigid, flexible & co-extruded products, including extruded tubing.

FABEXCO open_in_new

Location: Modesto, CA

Our profile extrusion capabilities are vast and adaptable to meet your specific needs. Whether you require rigid, flexible, dual, or tri-profile extrusions, we have the expertise and technology to deliver. We are dedicated to pushing the boundaries of what's possible in plastic extrusion, and we welcome the opportunity to tackle even the most challenging projects.

Absolute Custom Extrusions, Inc. open_in_new

Location: Milwaukee, WI

We have a long history of providing plastic extrusions. We will proudly serve you and we are committed to quality customer service. Our plastic extrusions are used in industries ranging from automotive to medical.

Plastic Extrusion Technologies open_in_new

Location: Middlefield, OH

At Plastic Extrusion Technologies, we specialize in the production of extruded plastics, catering to both large-scale manufacturing needs and smaller custom projects, all tailored to your precise specifications. We understand the importance of high-quality products, prompt delivery, and responsive service in today's fast-paced business landscape, and we are committed to meeting these expectations.

Pexco open_in_new

Location: Johns Creek, GA

As our name suggests, we are a leading custom extruder of plastic shrink tubing, flexible and rigid tubing, and profiles in standard or custom colors in a multitude of material options. We use state-of-the-art machinery for our extrusions and perform secondary operations on site, such as drilling, slotting, notching, etc. Pexco is ISO 9001 certified.

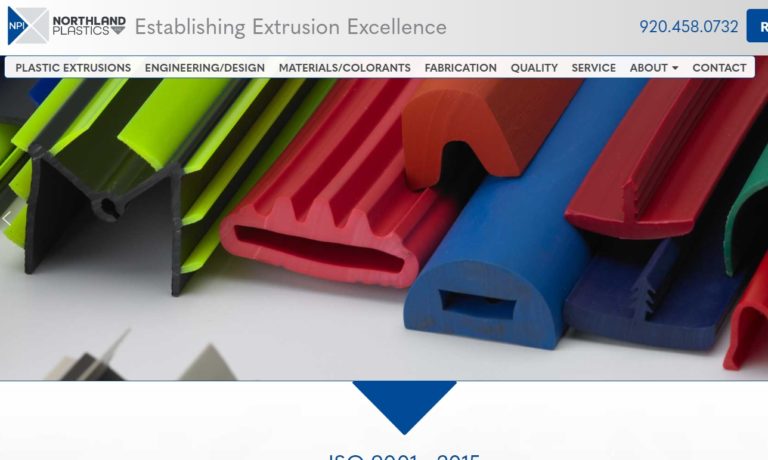

Northland Plastics, Inc. open_in_new

Location: Sheboygan, WI

At Northland Plastics, we are the experts in unique custom plastic extrusions. We specialize in single and dual durometer profile extrusions, vacuum calibration, automated inline fabrication, custom fabrication, and more. Custom colors and various additives are also available. As an ISO 9001:2015 company, we value product quality, timely delivery, competitive pricing, and excellent customer...

Petro Extrusion Technologies, Inc. open_in_new

Location: Middlesex, NJ

Petro specializes in plastic extrusions, offering our customers many capabilities, such as customized shapes & extruded tubing, along with tape application, coiling & angle cutting.

Polytec Plastics, Inc. open_in_new

Location: St. Charles, IL

We develop the most affordable and long lasting plastic extrusions. These extruded materials come in a variety of options and are Polytec Q-1 certified. We offer fast delivery and our customer service team is willing to design a perfect solution for your industry.

Keller Products open_in_new

Location: Manchester, NH

Since our founding more than 55 years ago, we at Keller have been the most innovative thinkers in the plastic profile extrusion industry. Our continued investment in new technology continues to pay off for our company and our customers; we are able to offer programs that eliminate tooling costs, we offer stocking and inventory programs and we can provide concept to tooling in less than five days.

GSH Industries, Inc. open_in_new

Location: Cleveland, OH

A plastic extrusion manufacturer of extruded plastic products, GSH Industries manufactures custom plastic extrusion profiles. We have continually expanded & attained our position as a preferred supplier of quality products & engineering ingenuity.

More Plastic Extruder Manufacturers

Components of Plastic Extruders

All types of plastic extruders have several common components that work together to ensure smooth operation and high-quality output. These components include:

Hopper

The hopper is where the plastic pellets or granules are loaded into the extruder.

Barrel

The barrel is the main part of the extruder where the plastic material is melted and mixed. It is typically heated using a heating element, and the temperature is carefully controlled to ensure the proper consistency of the plastic.

Screw

The screw is a key component of the extruder that moves the plastic material through the barrel and towards the die. The screw is typically driven by a motor, and it is designed to ensure consistent pressure and temperature throughout the extrusion process.

Die

The die is the final component of the extruder that shapes the plastic material as it is forced out of the machine. The die can be designed to create a wide range of shapes and sizes, depending on the needs of the manufacturer.

Variations of Plastic Extruders

There are several variations of plastic extruders, each with its own specific design and function. Some of the most common variations include:

Single Screw Extruders

Single screw extruders are the most common type of extruder and are used to produce a wide range of plastic products.

Twin Screw Extruders

Twin screw extruders are used for more complex applications, such as compounding and blending, and can handle a wider range of materials.

Co-Extruders

Co-extruders are used to create products with multiple layers of plastic material.

Hot Melt Extruders

Hot melt extruders are used to melt and apply adhesive materials to a variety of products.

Considerations Regarding Plastic Extruders

While plastic extruders are incredibly versatile and useful machines, there are several things to consider associated with their use. Some of these include:

Limited Material Compatibility

Not all types of plastic materials are compatible with extrusion, which limits the range of products that can be produced using this method.

High Cost of Equipment

Plastic extruders can be expensive to purchase and maintain, which can be a barrier to entry for smaller manufacturers.

Environmental Concerns

The use of plastics and plastic extruders has come under scrutiny in recent years due to environmental concerns over plastic waste and pollution.

Benefits of Plastic Extruders

Despite these limitations, plastic extruders offer several key benefits that make them an important part of the manufacturing process. Some of these benefits include:

Versatility

Plastic extruders can be used to create a wide range of products, from simple pipes and tubing to complex profiles and shapes.

High Quality Output

Plastic extruders can produce high-quality products with consistent dimensions and specifications.

Efficiency

Plastic extruders are highly efficient machines that can produce large volumes of products quickly and at a relatively low cost.

Applications of Plastic Extruders

Plastic extruders are used in a variety of industries and applications, including:

Manufacturing Plastic Pipes and Tubing

One of the most common uses for plastic extruders is in the production of plastic pipes and tubing. Extruders can produce pipes and tubing of various sizes, shapes, and materials, including PVC, polyethylene, and polypropylene.

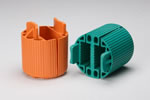

Extruding Plastic Profiles and Shapes

Extruders can also be used to create a variety of plastic profiles and shapes, including window frames, door frames, and trim pieces.

Producing Plastic Film and Sheets

Plastic extruders can produce thin plastic films and sheets of various sizes and materials. These films and sheets can be used for packaging, as well as for applications in industries such as agriculture and construction.

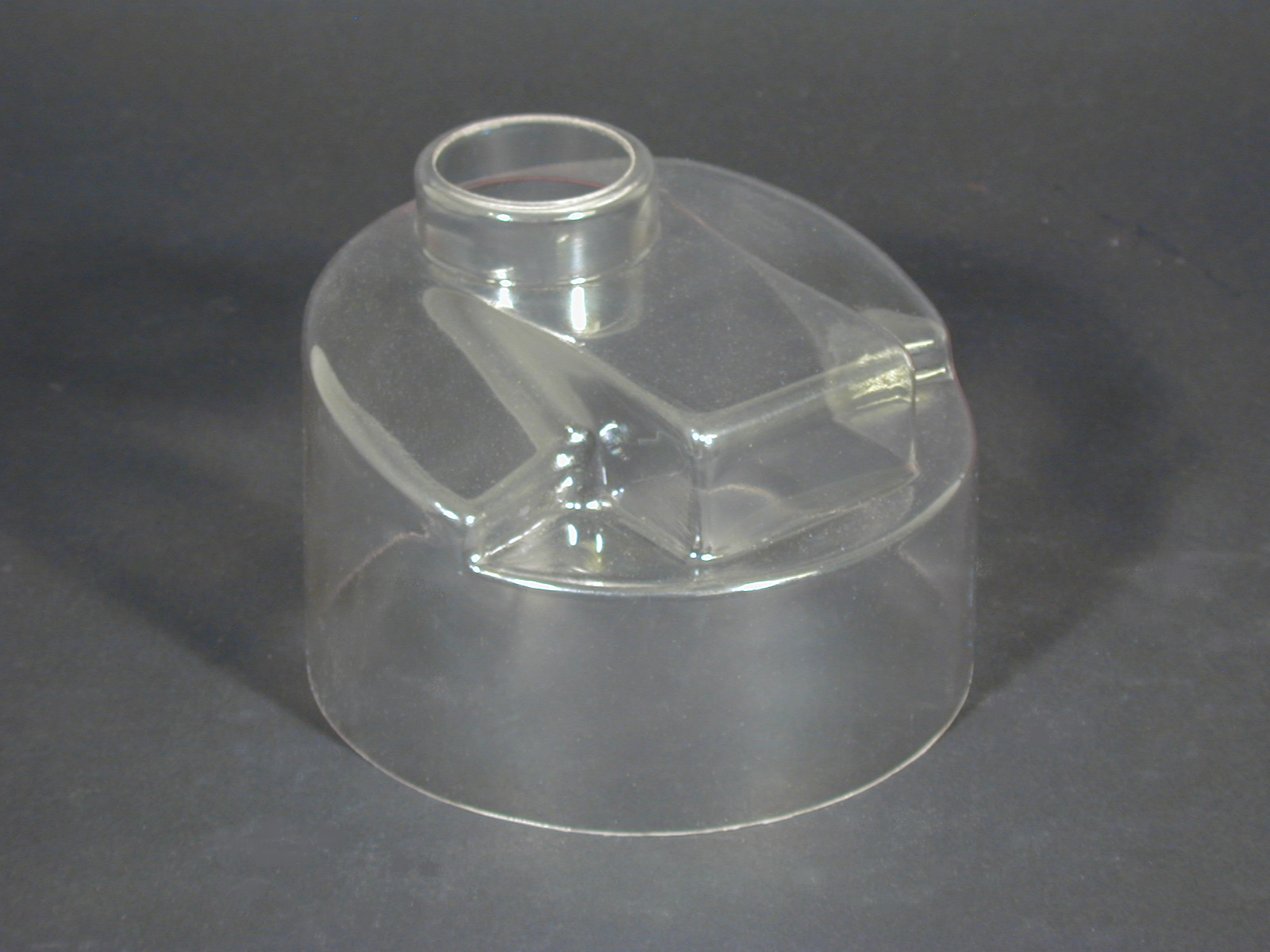

Manufacturing Plastic Bottles and Containers

Extruders are commonly used in the production of plastic bottles and containers for a wide range of products, including beverages, personal care items, and household cleaners.

Creating Plastic Granules and Pellets

Extruders can also be used to create plastic granules and pellets, which can be used as raw materials in the production of other plastic products.

Recycling Plastic Waste

Plastic extruders can be used in the recycling process to convert plastic waste into new products.

Creating Plastic Coatings

Extruders can produce plastic coatings that can be applied to a variety of surfaces, such as metal, wood, and plastic, to provide protection and improve appearance.

Choosing the Correct Plastic Extruder Manufacturer

To ensure you have the most beneficial outcome when purchasing a plastic extruder from a plastic extruder manufacturer, it is important to compare several companies using our directory of plastic extruder manufacturers. Each plastic extruder manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or to request a quote. Review each plastic extruder business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple plastic extruder companies with the same form.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services