Plastic extrusion and plastic co-extrusion processes are used to create solid plastic shapes known as plastic rods. These plastic rods have important applications in aerospace, electronics, petrochemicals, maritime, and transportation industries. During the plastic extrusion process, the raw plastic material undergoes the melting process. It is then pushed through a die which forms desired shapes and hardens during the cooling process. Read More…

Preferred Plastics, Inc. open_in_new

Location: Plainwell, MI

Preferred Plastics is an ISO 9001:2000-certified custom plastic extruder, specializing in rigid, flexible & co-extruded products, including extruded tubing.

FABEXCO open_in_new

Location: Modesto, CA

Our profile extrusion capabilities are vast and adaptable to meet your specific needs. Whether you require rigid, flexible, dual, or tri-profile extrusions, we have the expertise and technology to deliver. We are dedicated to pushing the boundaries of what's possible in plastic extrusion, and we welcome the opportunity to tackle even the most challenging projects.

Absolute Custom Extrusions, Inc. open_in_new

Location: Milwaukee, WI

We have a long history of providing plastic extrusions. We will proudly serve you and we are committed to quality customer service. Our plastic extrusions are used in industries ranging from automotive to medical.

Plastic Extrusion Technologies open_in_new

Location: Middlefield, OH

At Plastic Extrusion Technologies, we specialize in the production of extruded plastics, catering to both large-scale manufacturing needs and smaller custom projects, all tailored to your precise specifications. We understand the importance of high-quality products, prompt delivery, and responsive service in today's fast-paced business landscape, and we are committed to meeting these expectations.

Pexco open_in_new

Location: Johns Creek, GA

As our name suggests, we are a leading custom extruder of plastic shrink tubing, flexible and rigid tubing, and profiles in standard or custom colors in a multitude of material options. We use state-of-the-art machinery for our extrusions and perform secondary operations on site, such as drilling, slotting, notching, etc. Pexco is ISO 9001 certified.

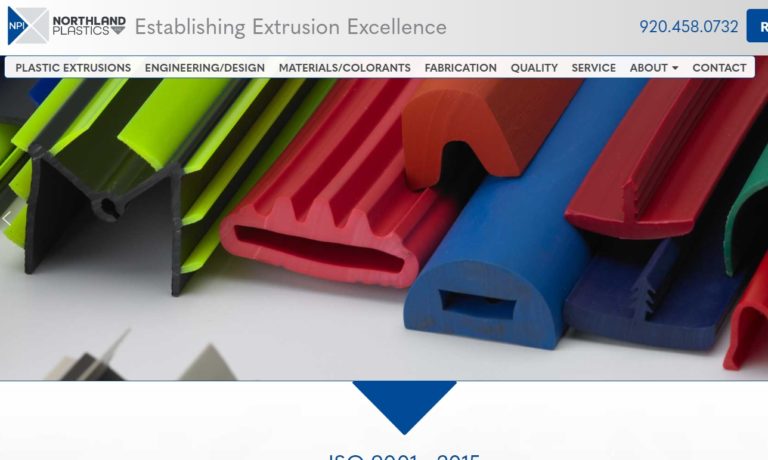

Northland Plastics, Inc. open_in_new

Location: Sheboygan, WI

At Northland Plastics, we are the experts in unique custom plastic extrusions. We specialize in single and dual durometer profile extrusions, vacuum calibration, automated inline fabrication, custom fabrication, and more. Custom colors and various additives are also available. As an ISO 9001:2015 company, we value product quality, timely delivery, competitive pricing, and excellent customer...

Petro Extrusion Technologies, Inc. open_in_new

Location: Middlesex, NJ

Petro specializes in plastic extrusions, offering our customers many capabilities, such as customized shapes & extruded tubing, along with tape application, coiling & angle cutting.

Polytec Plastics, Inc. open_in_new

Location: St. Charles, IL

We develop the most affordable and long lasting plastic extrusions. These extruded materials come in a variety of options and are Polytec Q-1 certified. We offer fast delivery and our customer service team is willing to design a perfect solution for your industry.

Keller Products open_in_new

Location: Manchester, NH

Since our founding more than 55 years ago, we at Keller have been the most innovative thinkers in the plastic profile extrusion industry. Our continued investment in new technology continues to pay off for our company and our customers; we are able to offer programs that eliminate tooling costs, we offer stocking and inventory programs and we can provide concept to tooling in less than five days.

GSH Industries, Inc. open_in_new

Location: Cleveland, OH

A plastic extrusion manufacturer of extruded plastic products, GSH Industries manufactures custom plastic extrusion profiles. We have continually expanded & attained our position as a preferred supplier of quality products & engineering ingenuity.

More Plastic Rod Manufacturers

Plastic rods can be used in the construction and commercial business sectors, to structurally support point of purchase displays, and in industrial equipment.

Manufacturing Plastic Rods

Plastic extrusion or plastic co-extrusion are methods used to manufacture plastic rods. The primary procedure used to manufacture plastic rods is known as plastic extrusion.

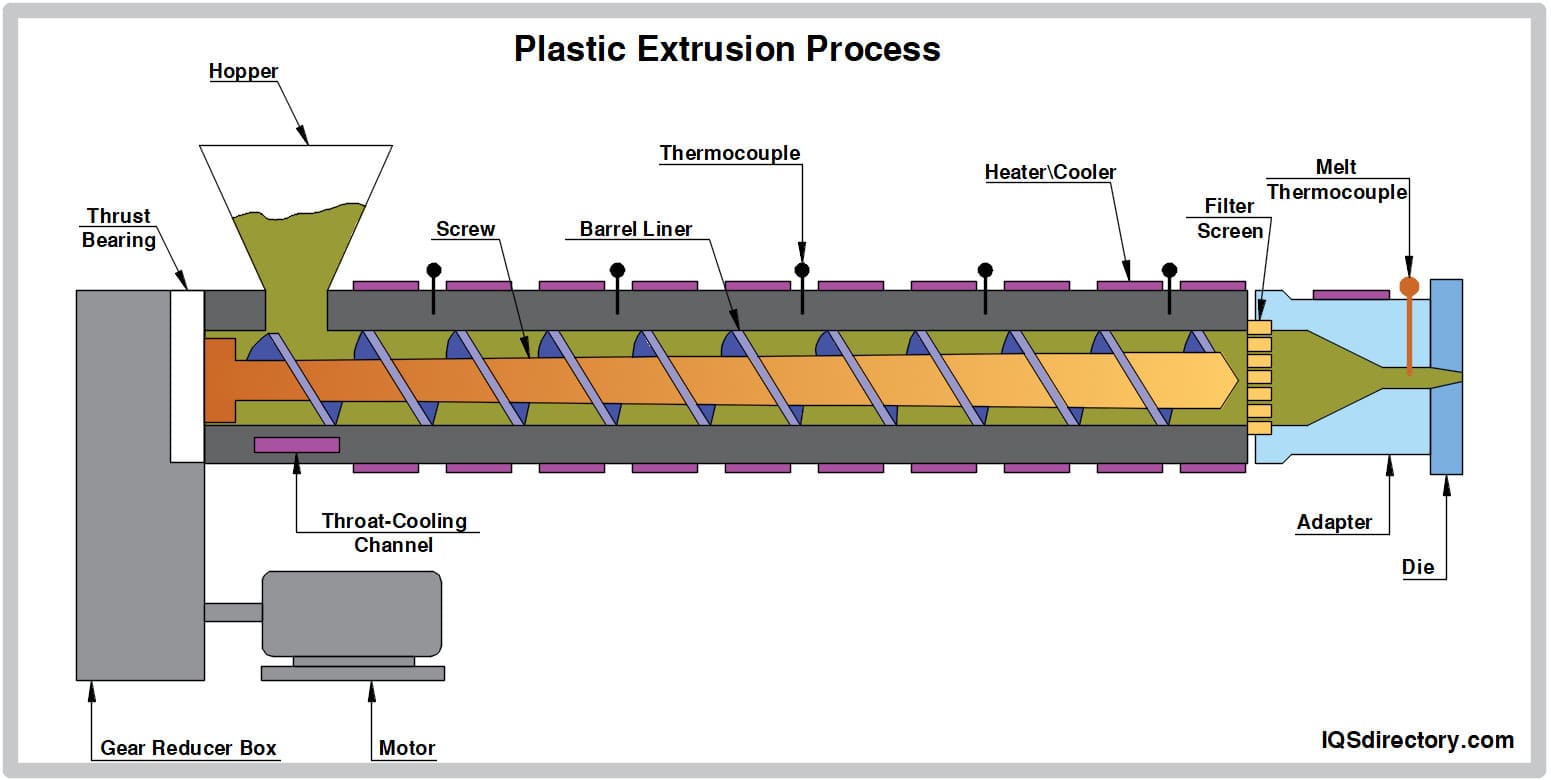

Plastic Extrusion Process

Typically, the basic compound material used in this plastic extrusion process starts as microplastic materials with a size of less than 5mm. Then, small beads, commonly referred to as resin, are gravity-fed into the barrel of the extruder from a top-mounted hopper. It is possible to blend colorants and UV inhibitors with the resin before they reach the hopper by adding them as additives in the form of pellets or liquid. From the perspective of extruder technology, the plastic extrusion process is similar to the plastic injection molding process, but it varies in that it is a continuous process.

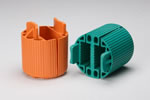

In plastic extrusion, similar profiles of the rods are produced in continuous lengths, usually with reinforcement. Afterward, the material enters through the feed throat, a hole close to the barrel's back, and contacts the screw. The purpose of this rotating screw, which typically rotates at 120 rpm, is to propel the plastic beads into the heated barrel. Due to factors like viscous heating, the temperature needed for extrusion is rarely the same as the barrel's fixed temperature.

Three or more separate PID-controlled heating zones in this barrel work together to raise the barrel's temperature from the back progressively. The plastic enters from this back toward the front. This lowers the possibility of overheating, which could lead to the breakdown of polymers. It also lets the plastic beads melt gradually as they are forced through the barrel. The molten plastic then leaves the barrel, and a screen pack removes any containment before it reaches the die.

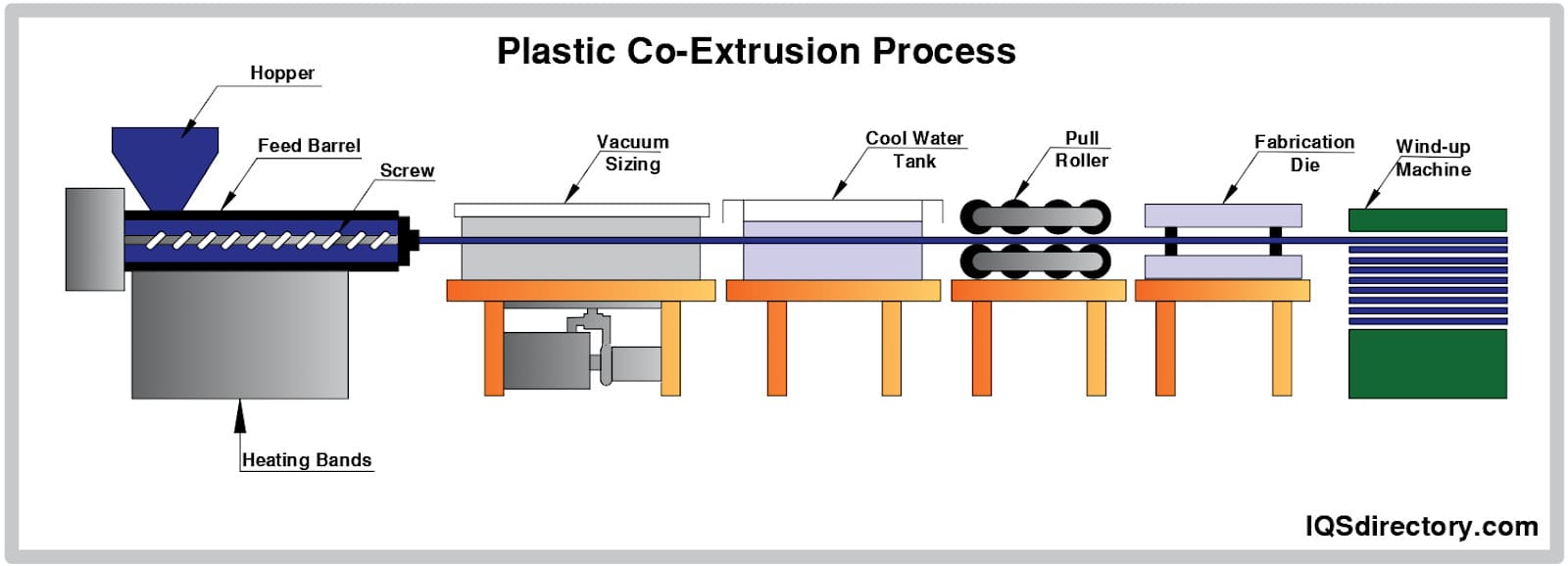

Plastic Co-Extrusion Process

Co-extrusion is a modified form of extrusion in which a single product is produced using a combination of two or more distinct materials. Plastic can occasionally be co-extruded with other non-plastic materials, such as metals. The task of melting the polymers used to manufacture the product is carried out by many extruders directed toward a single die.

Types of Extruders

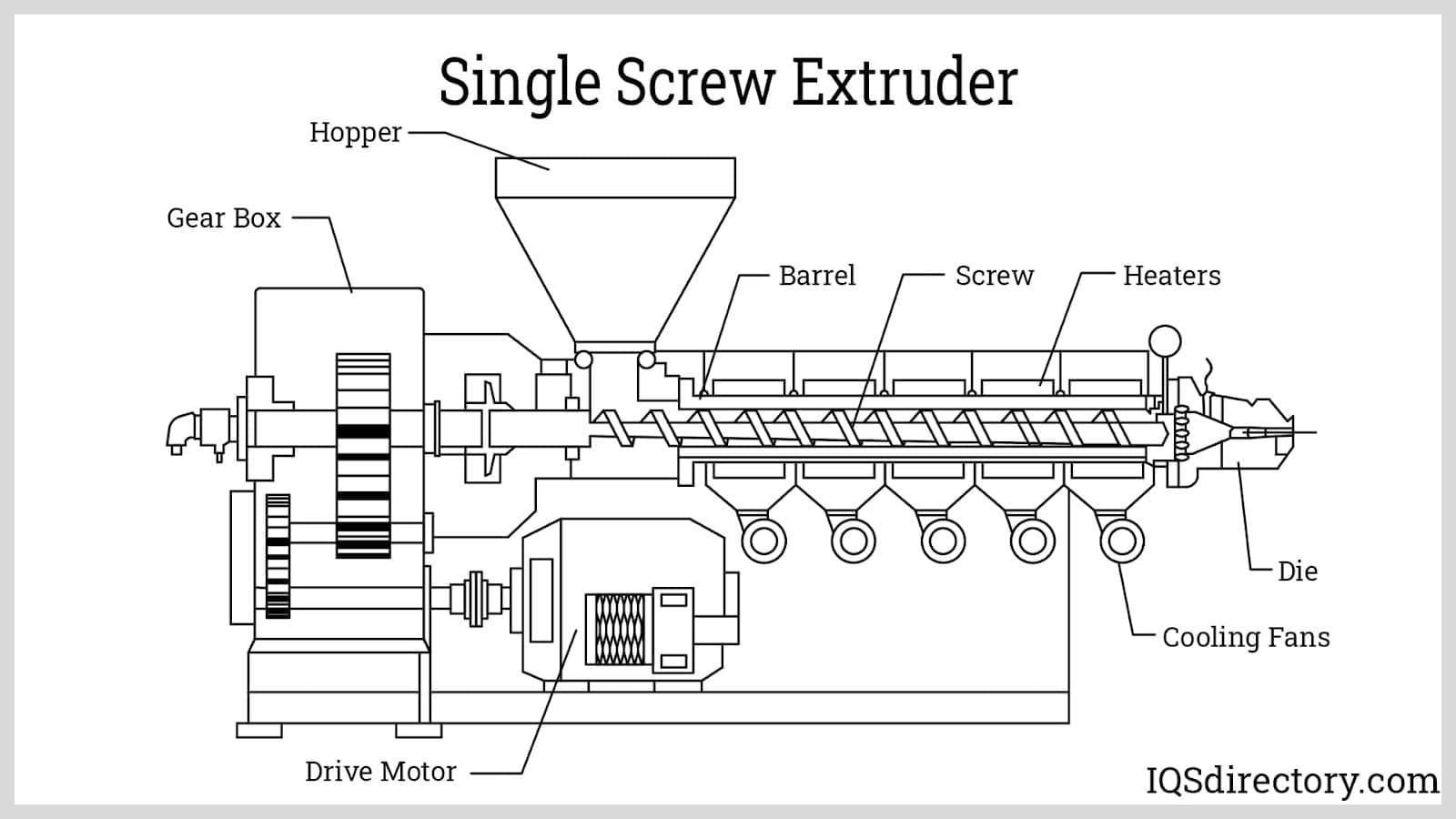

There are many different types of extruder designs for use in extrusion processes. However, continuous and discontinuous extruders are the most common classes of extruders. The main difference between continuous extruders and discontinuous extruders is that discontinuous extruders have reciprocating parts, while continuous extruders have rotating parts. The two additional categories for continuous extruders are screw extruders and drum or disk extruders.

Screw Extruders

Due to their low cost, toughness, simple design, great performance, and reliability, screw extruders are the most popular continuous extruders. Three zones with three different geometries are present in a typical single-screw extruder. The enclosed zones are feed, metering, and compression zones. A constant pitch and variable screw depth creates these zones.

Disk Extruders

Disk extruders facilitate the extrusion process by using disks or drums. Disk extruders are also known as screwless extruders. Viscous drag transfer is used to operate most disk extruder models.

Drum Extruders

This kind of extruder operates by using a spinning drum and barrel. The polymeric material is fed into the annular space between the barrel and the drum in drum extruders.

Applications of Plastic Rods

- Raw materials for making seals

- Support material for displays

- Prestressing tendons

Advantages of Plastic Rods

- High wear resistance

- High impact strength

- High chemical resistance

- Less expensive

- Lightweight

Disadvantages of Plastic Rods

- Not biodegradable

- Toxic

- Lead to pollution

- Non-renewable

- Cannot resist high temperatures

- Prone to damage

Choosing the Correct Plastic Rod Supplier

To ensure you have the most beneficial outcome when purchasing plastic rods from a plastic rod supplier, it is important to compare several companies using our directory of plastic rod suppliers. Each plastic rod supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or request a quote. Review each plastic rod business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple plastic rod companies with the same form.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services