Keeping wires and cables organized and safe can be a challenge in any setting. Inefficient cable management can lead to tripping hazards, damage to cables, and a general eyesore. PVC channels provide a simple and effective solution to these problems by organizing and protecting wires and cables.. Read More…

Preferred Plastics, Inc. open_in_new

Location: Plainwell, MI

Preferred Plastics is an ISO 9001:2000-certified custom plastic extruder, specializing in rigid, flexible & co-extruded products, including extruded tubing.

FABEXCO open_in_new

Location: Modesto, CA

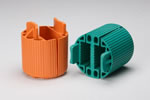

Our profile extrusion capabilities are vast and adaptable to meet your specific needs. Whether you require rigid, flexible, dual, or tri-profile extrusions, we have the expertise and technology to deliver. We are dedicated to pushing the boundaries of what's possible in plastic extrusion, and we welcome the opportunity to tackle even the most challenging projects.

Absolute Custom Extrusions, Inc. open_in_new

Location: Milwaukee, WI

We have a long history of providing plastic extrusions. We will proudly serve you and we are committed to quality customer service. Our plastic extrusions are used in industries ranging from automotive to medical.

Plastic Extrusion Technologies open_in_new

Location: Middlefield, OH

At Plastic Extrusion Technologies, we specialize in the production of extruded plastics, catering to both large-scale manufacturing needs and smaller custom projects, all tailored to your precise specifications. We understand the importance of high-quality products, prompt delivery, and responsive service in today's fast-paced business landscape, and we are committed to meeting these expectations.

Pexco open_in_new

Location: Johns Creek, GA

As our name suggests, we are a leading custom extruder of plastic shrink tubing, flexible and rigid tubing, and profiles in standard or custom colors in a multitude of material options. We use state-of-the-art machinery for our extrusions and perform secondary operations on site, such as drilling, slotting, notching, etc. Pexco is ISO 9001 certified.

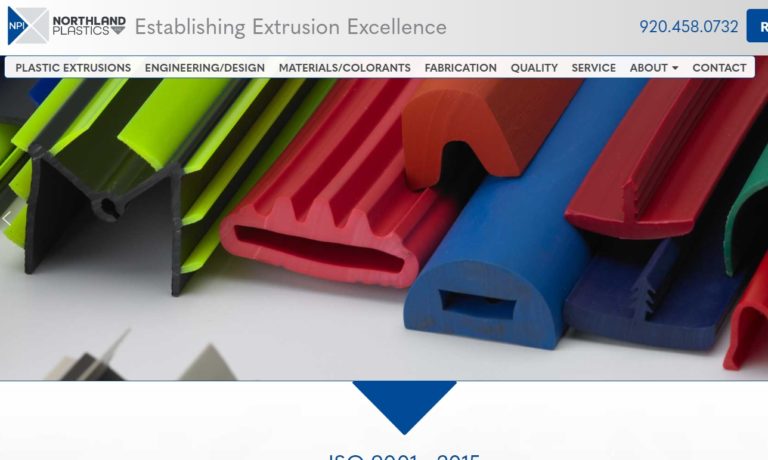

Northland Plastics, Inc. open_in_new

Location: Sheboygan, WI

At Northland Plastics, we are the experts in unique custom plastic extrusions. We specialize in single and dual durometer profile extrusions, vacuum calibration, automated inline fabrication, custom fabrication, and more. Custom colors and various additives are also available. As an ISO 9001:2015 company, we value product quality, timely delivery, competitive pricing, and excellent customer...

Petro Extrusion Technologies, Inc. open_in_new

Location: Middlesex, NJ

Petro specializes in plastic extrusions, offering our customers many capabilities, such as customized shapes & extruded tubing, along with tape application, coiling & angle cutting.

Polytec Plastics, Inc. open_in_new

Location: St. Charles, IL

We develop the most affordable and long lasting plastic extrusions. These extruded materials come in a variety of options and are Polytec Q-1 certified. We offer fast delivery and our customer service team is willing to design a perfect solution for your industry.

Keller Products open_in_new

Location: Manchester, NH

Since our founding more than 55 years ago, we at Keller have been the most innovative thinkers in the plastic profile extrusion industry. Our continued investment in new technology continues to pay off for our company and our customers; we are able to offer programs that eliminate tooling costs, we offer stocking and inventory programs and we can provide concept to tooling in less than five days.

GSH Industries, Inc. open_in_new

Location: Cleveland, OH

A plastic extrusion manufacturer of extruded plastic products, GSH Industries manufactures custom plastic extrusion profiles. We have continually expanded & attained our position as a preferred supplier of quality products & engineering ingenuity.

More PVC Channel Manufacturers

Components of PVC Channels

PVC channels consist of three main components: a cover, a base, and a divider. The cover provides a protective layer for the wires and cables. The base attaches to the surface and holds the wires and cables in place. The divider creates separate compartments for wires and cables to prevent them from tangling. The combination of these three components ensures that the wires and cables are organized and protected.

Variations of PVC Channels

There are several variations of PVC channels, each with specific applications. Surface-mounted PVC channels are designed to be mounted on walls or ceilings, making them an excellent option for home and office organization. Recessed PVC channels are installed into the wall or ceiling, creating a flush and seamless look that is perfect for entertainment and AV systems. Adhesive-backed PVC channels are a quick and easy solution for temporary installations. Wide-base PVC channels are perfect for heavy-duty applications, while narrow-base PVC channels are ideal for areas with limited space.

Considerations Regarding PVC Channels

While PVC channels are an excellent cable management solution, they do have some challenges. The load capacity of PVC channels is limited, and they are not suitable for extreme temperatures. Additionally, PVC channels are not suitable for outdoor use without UV stabilizers.

Benefits of PVC Channels

Despite their challenges, PVC channels offer several benefits, making them an excellent choice for cable management. They are easy to install, cost-effective, and versatile in design and application. PVC channels reduce tripping hazards, making them an ideal choice for areas with heavy foot traffic. Additionally, PVC channels improve aesthetics by hiding wires and cables.

Applications of PVC Channels

PVC channels have a wide range of applications, including:

Home and Office Organization

PVC channels are an excellent solution for managing cables and wires in homes and offices. These channels can be installed on walls, ceilings, or floors, keeping cables out of sight and organized. This reduces clutter and prevents tripping hazards. PVC channels can be used to organize cables for computers, printers, audio systems, and other electronic devices.

Cable Management in IT and Networking

In IT and networking applications, the organization and protection of cables are critical. PVC channels provide an efficient way to manage and protect cables in server rooms, data centers, and other IT environments. These channels can be used to segregate power and data cables, ensuring that they do not interfere with each other. PVC channels also protect cables from damage caused by vibration, moisture, and dust.

Entertainment and AV Systems

PVC channels are an excellent solution for managing cables in entertainment and audio-visual (AV) systems. Recessed PVC channels can be installed into walls or ceilings, creating a seamless look that complements the aesthetics of the room. These channels can be used to conceal cables for televisions, speakers, and other audio-visual components. They also protect cables from damage caused by pets, children, or accidental bumps.

Automotive Wiring

PVC channels are also used in automotive wiring applications. These channels can be used to protect and organize wiring for electrical components in cars, trucks, and other vehicles. PVC channels are lightweight and durable, making them ideal for use in vehicles. They also provide protection from moisture and vibration, which can cause damage to wiring.

Industrial Wiring and Control Systems

In industrial settings, PVC channels are commonly used to manage wiring and control systems. These channels can be used to organize and protect wiring for motors, control panels, and other electrical components. PVC channels provide protection from dust, moisture, and other environmental hazards. They are also resistant to chemicals and oils, making them an ideal choice for use in factories and other industrial settings.

Marine Wiring

PVC channels are also suitable for marine wiring applications. They can be used to organize and protect wiring for electrical components in boats, yachts, and other watercraft. PVC channels are resistant to moisture and saltwater, which can cause damage to wiring. They also provide protection from UV rays, which can cause cables to degrade over time.

Choosing the Correct PVC Channel Supplier

To ensure you have the most positive outcome when purchasing PVC channels from a PVC channel supplier, it is important to compare several companies using our directory of PVC channel suppliers. Each PVC channel supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or to request a quote. Review each PVC channel business website using our proprietary website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple PVC channel businesses with the same form.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services