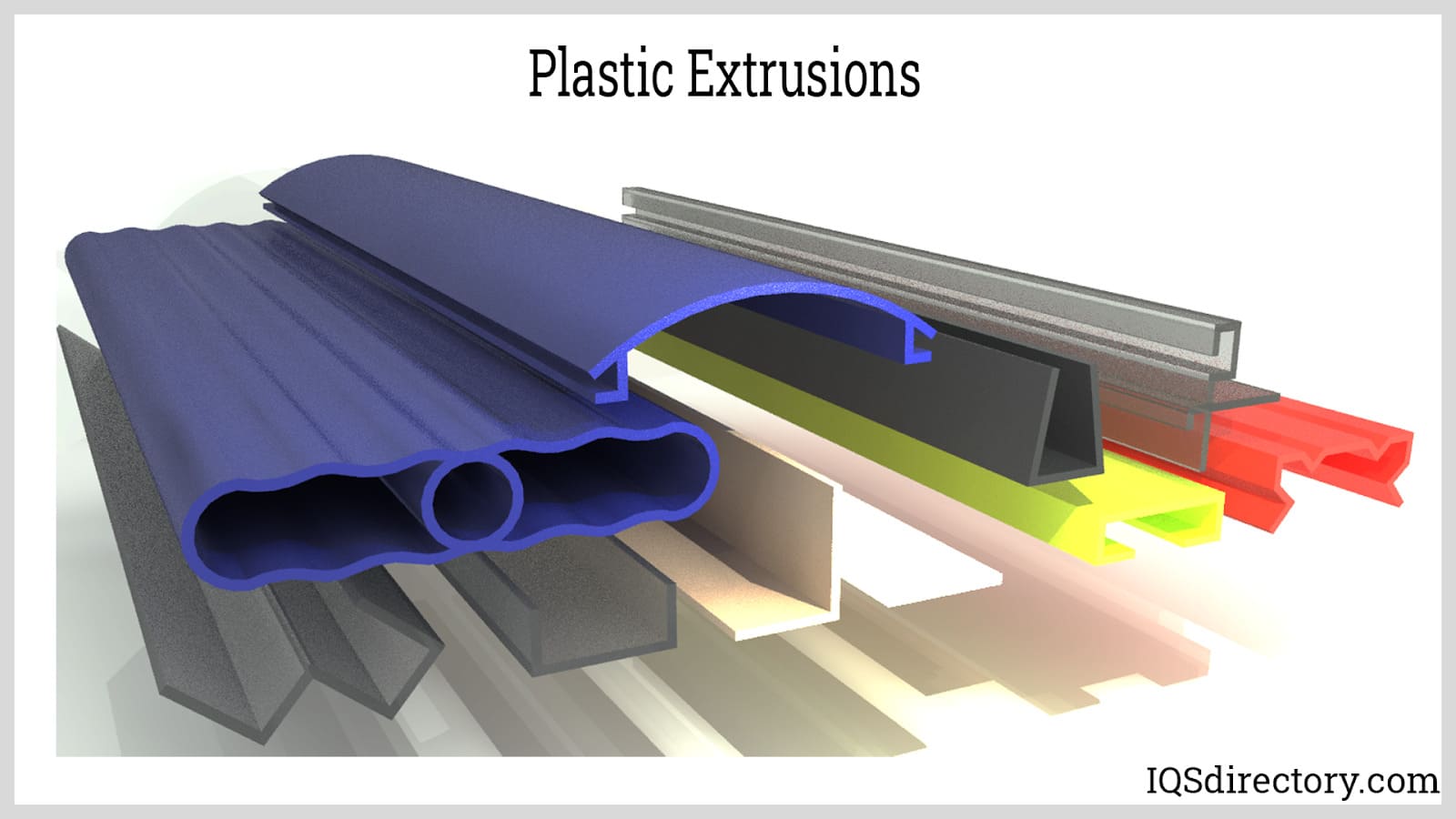

A plastic strip is a plastic shape made from continuous fabrication processes. There are a variety of plastic strips, and they are often placed in doorways for climate control in industries and public places. Many of the plastic strip varieties are characterized by narrowness and length.Read More…

Preferred Plastics, Inc. open_in_new

Location: Plainwell, MI

Preferred Plastics is an ISO 9001:2000-certified custom plastic extruder, specializing in rigid, flexible & co-extruded products, including extruded tubing.

SFR Industries Inc. open_in_new

Location: Cadott, WI

Since 1978, SFR has been a leader in custom plastic profile extrusions, specializing in vinyl polymers for a variety of industries ranging from commercial furniture and store fixtures to industrial applications.

FABEXCO open_in_new

Location: Modesto, CA

Our profile extrusion capabilities are vast and adaptable to meet your specific needs. Whether you require rigid, flexible, dual, or tri-profile extrusions, we have the expertise and technology to deliver. We are dedicated to pushing the boundaries of what's possible in plastic extrusion, and we welcome the opportunity to tackle even the most challenging projects.

Absolute Custom Extrusions, Inc. open_in_new

Location: Milwaukee, WI

We have a long history of providing plastic extrusions. We will proudly serve you and we are committed to quality customer service. Our plastic extrusions are used in industries ranging from automotive to medical.

Plastic Extrusion Technologies open_in_new

Location: Middlefield, OH

At Plastic Extrusion Technologies, we specialize in the production of extruded plastics, catering to both large-scale manufacturing needs and smaller custom projects, all tailored to your precise specifications. We understand the importance of high-quality products, prompt delivery, and responsive service in today's fast-paced business landscape, and we are committed to meeting these expectations.

Pexco open_in_new

Location: Johns Creek, GA

As our name suggests, we are a leading custom extruder of plastic shrink tubing, flexible and rigid tubing, and profiles in standard or custom colors in a multitude of material options. We use state-of-the-art machinery for our extrusions and perform secondary operations on site, such as drilling, slotting, notching, etc. Pexco is ISO 9001 certified.

Northland Plastics, Inc. open_in_new

Location: Sheboygan, WI

At Northland Plastics, we are the experts in unique custom plastic extrusions. We specialize in single and dual durometer profile extrusions, vacuum calibration, automated inline fabrication, custom fabrication, and more. Custom colors and various additives are also available. As an ISO 9001:2015 company, we value product quality, timely delivery, competitive pricing, and excellent customer...

Petro Extrusion Technologies, Inc. open_in_new

Location: Middlesex, NJ

Petro specializes in plastic extrusions, offering our customers many capabilities, such as customized shapes & extruded tubing, along with tape application, coiling & angle cutting.

Polytec Plastics, Inc. open_in_new

Location: St. Charles, IL

We develop the most affordable and long lasting plastic extrusions. These extruded materials come in a variety of options and are Polytec Q-1 certified. We offer fast delivery and our customer service team is willing to design a perfect solution for your industry.

Keller Products open_in_new

Location: Manchester, NH

Since our founding more than 55 years ago, we at Keller have been the most innovative thinkers in the plastic profile extrusion industry. Our continued investment in new technology continues to pay off for our company and our customers; we are able to offer programs that eliminate tooling costs, we offer stocking and inventory programs and we can provide concept to tooling in less than five days.

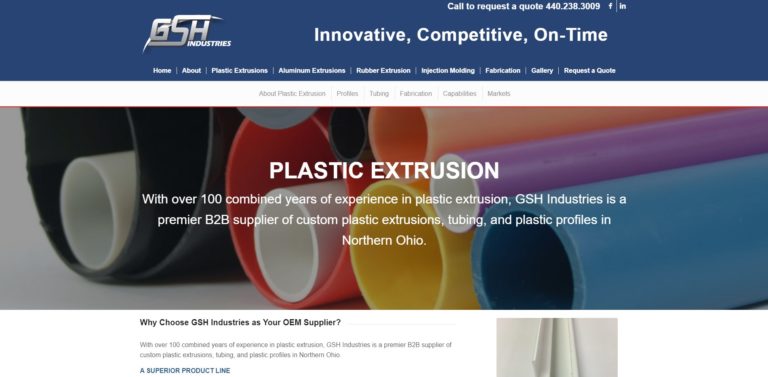

GSH Industries, Inc. open_in_new

Location: Cleveland, OH

A plastic extrusion manufacturer of extruded plastic products, GSH Industries manufactures custom plastic extrusion profiles. We have continually expanded & attained our position as a preferred supplier of quality products & engineering ingenuity.

More Plastic Strip Manufacturers

They are used as building trim, collators for nails in nail guns, furniture components, and other multiple purposes. Some rigid plastic strips can be made from multiple plastic materials, including low and high-density polystyrene, PET, polyethylene, and many other plastic materials.

The materials used to make plastic strips are chosen based on their qualities of durability, weather resistance, strength, and other relevant qualities. For example, PVC is chosen due to its resistance to UV rays. The process of manufacturing plastic strips is called extrusion. It is a fabrication process that is continuous. This makes it more suitable for the creation of plastic strips of long length. A collection of raw plastic materials are used to produce plastic strips by placing them in a hopper suspended above an extruder.

How Plastic Strips are Manufactured

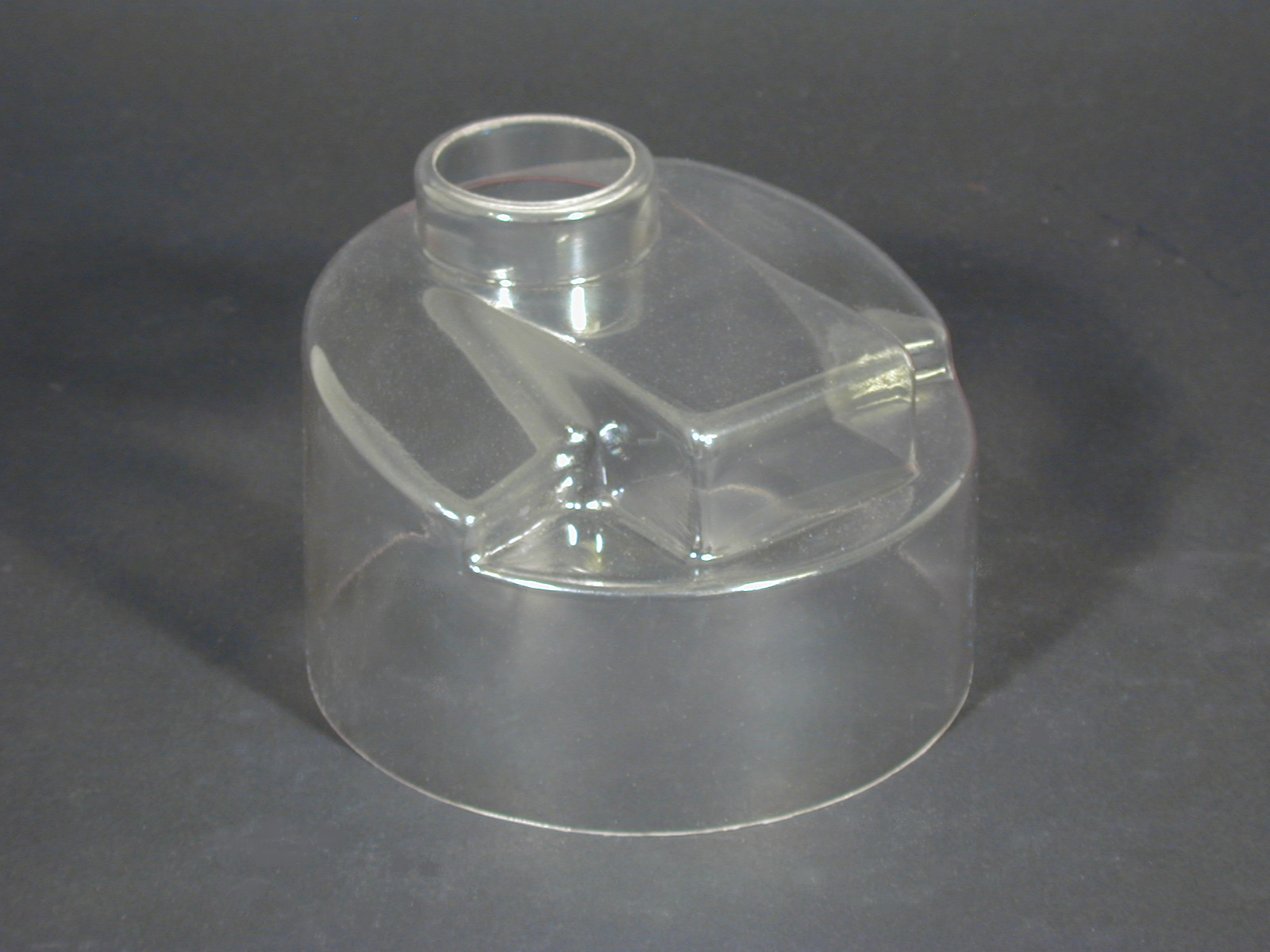

Plastic strips are manufactured from the extrusion process. Plastic extrusion is a high-volume manufacturing process in which a polymer material enriched with the desired additives is melted and then formed continuously.

The raw materials are in the form of granulates. They are gravity fed into the hopper through the feed throat. They then drop on a rotating screw. An electric motor is used to provide the rotation of the screw. The screw rotation will force the plastic polymer through a heated barrel. While the plastic is conveyed through the barrel, the channel of the screw decreases, and the plastic is compressed.

The plastic is melted and reaches the end of the screw, where it is mixed and pushed through a screen pack. Finally, the melt is pushed through the die. The die forms the desired profile and shape of the final product. The extruder then exits the extruder, and it is pulled and cooled. The method of cooling depends on the profile and shape of the extrusion.

Types of Plastic Strips

The different types of plastic strips include:

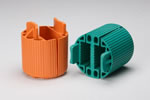

Polypropylene Plastic Strips

Polypropylene plastic strips have good chemical, fatigue, and temperature resistance. However, it is difficult to form this material because of its narrow thermoforming temperature window. Webbing also can be a problem.

PP has a semi-crystalline nature, increasing the post-forming shrinkage rates. Talc is used as a filling to improve these properties.

Acrylonitrile Butadiene Styrene Strips

These are one of the most versatile and widely used plastics. ABS has a very wide forming temperature range, making it relatively easy to form. In addition, ABS strips exhibit good dimensional stability, which makes them easier to trim.

Acrylic Plastic Strips

Acrylic plastic strips are versatile products. They are easy to machine, screen print, and polish and have improved resistance to impacts.

PVC Plastic Strips

PVC plastic strips are stiff strips with good resistance to impacts. Their fabrication, welding, and thermoforming are easy, but they become brittle at low temperatures.

Applications of Plastic Strips

Plastic strips are mostly used in consumer, industrial, and commercial applications. They are used to create plastic frames or trims that function as secondary doorways or barriers. These facilitate energy efficiency and limit the loss of cold or hot air. The following is a list of the common applications and uses of plastic strips:

Construction

- Fences

- Edging

- Weather-stripping

- Post

- Tubing

- Pipe

- Window frames

Industrial

- Machine trim

- Machine protectors

- Tracks

- Equipment trim and protectors

- Electrical wire covers

Benefits of Plastic Strips

- Low maintenance

- Cost-effective

- Prevent 80-90% of air loss through doors

- Enhance hygiene

- Reduce product spoilage

- Reduce wear and tear on switches, motors, and compressors

- Restrict air pollutants from entering

- Perform well in outdoor environments

- Easy to fabricate

- Impact-resistant

- Strong and stiff

Choosing the Correct Plastic Strip Manufacturer

To ensure you have the most constructive outcome when purchasing plastic strips from a plastic strip manufacturer, it is important to compare several companies using our directory of plastic strip manufacturers. Each plastic strip manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or request a quote. Review each plastic strip business website using our proprietary website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple plastic strip companies with the same form.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services