In building projects, there are ledges and edges that serve as protective barriers, limit traffic, or serve as a warning. In other instances, they can be a decorative finishing touch that enhances and adds to a design. Barriers, edges, fences, and other forms of separating methods require a finishing touch that completes their design. Read More…

Preferred Plastics, Inc. open_in_new

Location: Plainwell, MI

Preferred Plastics is an ISO 9001:2000-certified custom plastic extruder, specializing in rigid, flexible & co-extruded products, including extruded tubing.

SFR Industries Inc. open_in_new

Location: Cadott, WI

Since 1978, SFR has been a leader in custom plastic profile extrusions, specializing in vinyl polymers for a variety of industries ranging from commercial furniture and store fixtures to industrial applications.

FABEXCO open_in_new

Location: Modesto, CA

Our profile extrusion capabilities are vast and adaptable to meet your specific needs. Whether you require rigid, flexible, dual, or tri-profile extrusions, we have the expertise and technology to deliver. We are dedicated to pushing the boundaries of what's possible in plastic extrusion, and we welcome the opportunity to tackle even the most challenging projects.

Absolute Custom Extrusions, Inc. open_in_new

Location: Milwaukee, WI

We have a long history of providing plastic extrusions. We will proudly serve you and we are committed to quality customer service. Our plastic extrusions are used in industries ranging from automotive to medical.

Plastic Extrusion Technologies open_in_new

Location: Middlefield, OH

At Plastic Extrusion Technologies, we specialize in the production of extruded plastics, catering to both large-scale manufacturing needs and smaller custom projects, all tailored to your precise specifications. We understand the importance of high-quality products, prompt delivery, and responsive service in today's fast-paced business landscape, and we are committed to meeting these expectations.

Pexco open_in_new

Location: Johns Creek, GA

As our name suggests, we are a leading custom extruder of plastic shrink tubing, flexible and rigid tubing, and profiles in standard or custom colors in a multitude of material options. We use state-of-the-art machinery for our extrusions and perform secondary operations on site, such as drilling, slotting, notching, etc. Pexco is ISO 9001 certified.

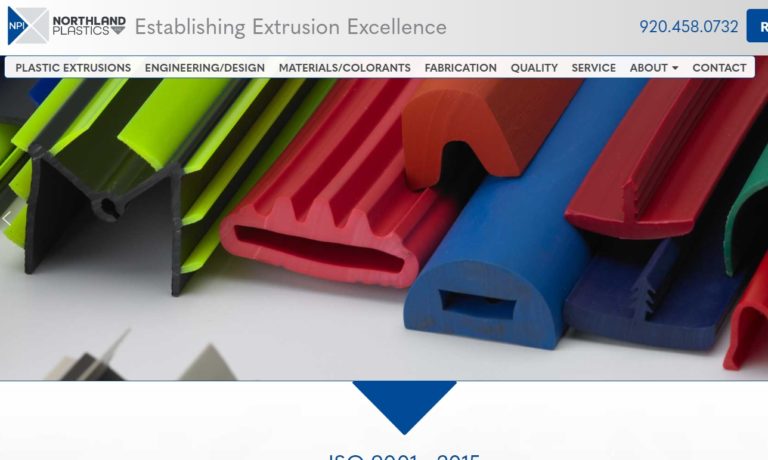

Northland Plastics, Inc. open_in_new

Location: Sheboygan, WI

At Northland Plastics, we are the experts in unique custom plastic extrusions. We specialize in single and dual durometer profile extrusions, vacuum calibration, automated inline fabrication, custom fabrication, and more. Custom colors and various additives are also available. As an ISO 9001:2015 company, we value product quality, timely delivery, competitive pricing, and excellent customer...

Petro Extrusion Technologies, Inc. open_in_new

Location: Middlesex, NJ

Petro specializes in plastic extrusions, offering our customers many capabilities, such as customized shapes & extruded tubing, along with tape application, coiling & angle cutting.

Polytec Plastics, Inc. open_in_new

Location: St. Charles, IL

We develop the most affordable and long lasting plastic extrusions. These extruded materials come in a variety of options and are Polytec Q-1 certified. We offer fast delivery and our customer service team is willing to design a perfect solution for your industry.

Keller Products open_in_new

Location: Manchester, NH

Since our founding more than 55 years ago, we at Keller have been the most innovative thinkers in the plastic profile extrusion industry. Our continued investment in new technology continues to pay off for our company and our customers; we are able to offer programs that eliminate tooling costs, we offer stocking and inventory programs and we can provide concept to tooling in less than five days.

GSH Industries, Inc. open_in_new

Location: Cleveland, OH

A plastic extrusion manufacturer of extruded plastic products, GSH Industries manufactures custom plastic extrusion profiles. We have continually expanded & attained our position as a preferred supplier of quality products & engineering ingenuity.

More Plastic Edge Trim Manufacturers

Plastic Edge Trim

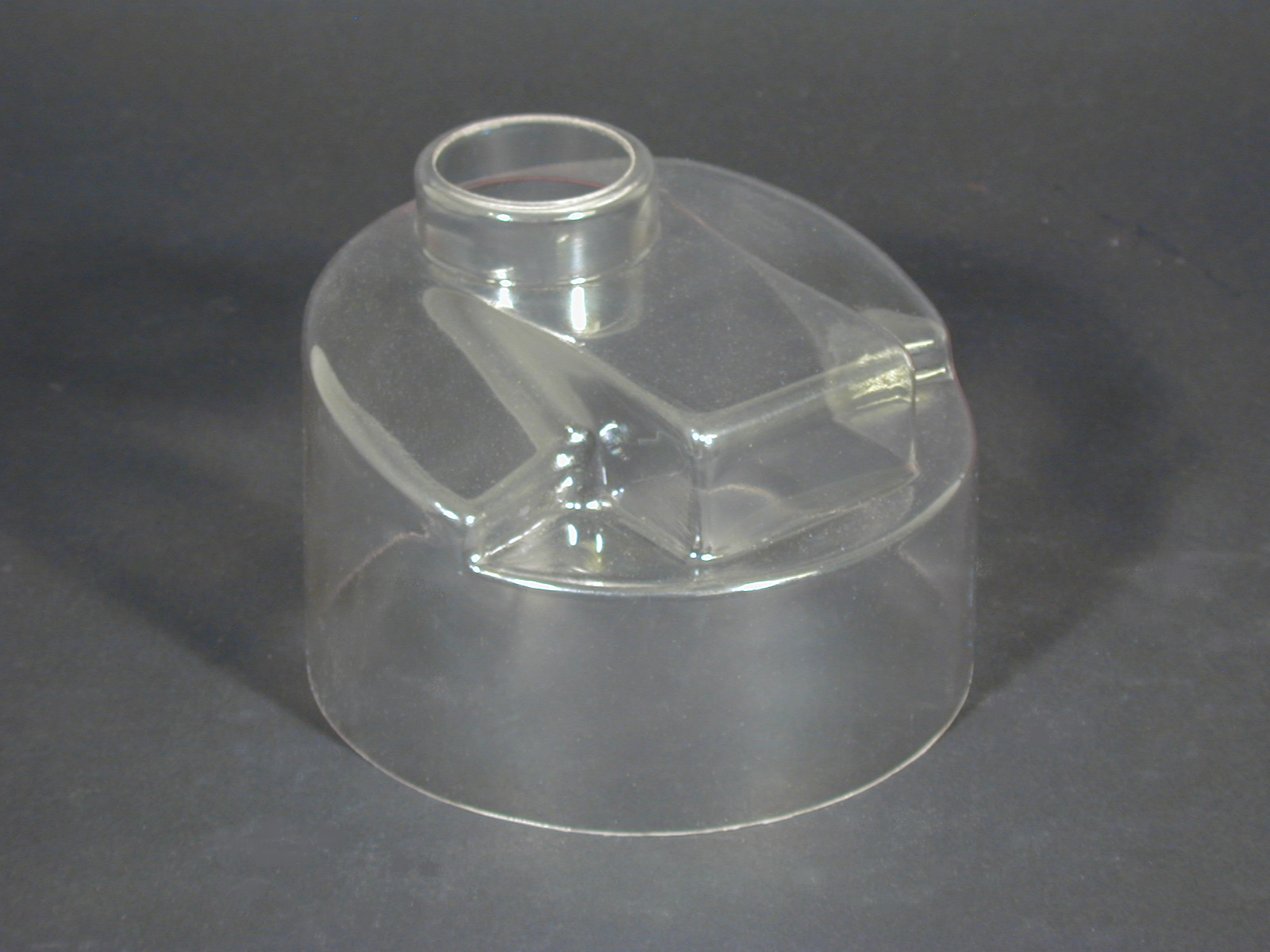

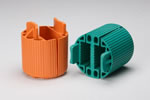

To meet the need of covering an edge, completing a design, or protecting the top of a surface from abuse, plastic extrusion engineers developed plastic edge trim that can be easily installed but provide an aesthetically appealing appearance. Since the extrusion process provides the ability to develop and create any shape or design, plastic edge trim can be custom configured to fit the needs of any application.

What is Plastic Edge Trim?

The initial stage in the development of plastic edge trim is design. Though plastics can be extruded into any shape, configuration, or design to fit the edge trim application, they have to be engineered to the exact dimensions. After the design and dimensions are determined, the next step is to choose the type of polymer.

It can be assumed that any type of plastic can be fitted to an edge as a form of protection. When making the choice of plastic type for an edge trim, it is important to choose one that will fit the conditions and withstand the potential abuse. The location where it will be installed is an important guiding factor. If it will be used indoors in an office building or apartment complex, the trim will not be required to be so robust. Trim for outdoor use or industrial operations need to be sturdier, stable, and resilient.

Once the design parameters have been established and the type of material selected, the lengths will need to be decided upon and the method of connection and seal will need to be determined. These factors will be influenced by the type of material that has been chosen.

Plastic Edge Trim Materials

The term plastic is a generic term that can be applied to any form of material that looks, feels, and reacts like plastic. In reality, there are many varieties of plastics, some of which have been patented and perfected for specific applications. Plastic edge trim producers have a catalog of all the various types of plastics and their properties. The key to using a plastic as an edge trim is knowledge of the types of properties it has since the properties determine the plastic’s resilience.

Regardless of the type of plastic, they all begin with the same basic elements, which include a resin that is melted and shaped to the specification of the application. The beauty of producing a plastic edge trim from extrusion is the precise design of the die through which the plastic is forced to match the edge trim profile.

There are many situations where you will see rubber used as an edge trim. Rubber is a logical choice but does not have the major benefits of using plastic, the first of which is cost. Rubber is an exceptionally sturdy and resilient material that can withstand a wide variety of stressful conditions. Plastic has all of the characteristics of rubber but at a lower cost, and it is easier to process.

Colors of Plastic Edge Trim

This aspect of plastic edge trim is one of its most outstanding traits. Plastic can be produced in any color to fit the needs of the application. For safety gates, it can be configured in bright yellow or red. When used as a decorative or accent material, it can be made in subtle colors.

Plastic edge trim producers provide customers with a standard set of colors they use for many of their projects. In cases where the customer requires a custom color, manufacturers can easily match the specifications. In the manufacture of plastic products, color is never an issue.

Co-Extruded Plastic Edge Trim

Much of the discussion surrounding plastic edge trim is usually in regard to a single polymer that is extruded to the shape and design for the application. This formula produces highly durable products that are capable of withstanding any climactic or abusive conditions.

There are cases where a single polymer mixture does not provide sufficient strength to meet the necessary requirements. To meet the challenge of such circumstances, two exceptionally strong polymers can be extruded together to provide twice the protection and endurance.

Co-extrusion can blend rigid and flexible materials in any color with thin cap stock over a more stringent and rugged substrate. The combinations can be blended and tested to ensure they meet specified standards exactly.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services