Polymer extrusion is a widely used production method in the plastics sector since it is accessible and simple to use, whether it be to produce one hundred yards of pipe-tubing, plastic sheets, or a thousand crazy straws. The plastic’s molecules are also aligned during extrusion to increase the piece’s strength along its length. Read More…

Preferred Plastics, Inc. open_in_new

Location: Plainwell, MI

Preferred Plastics is an ISO 9001:2000-certified custom plastic extruder, specializing in rigid, flexible & co-extruded products, including extruded tubing.

FABEXCO open_in_new

Location: Modesto, CA

Our profile extrusion capabilities are vast and adaptable to meet your specific needs. Whether you require rigid, flexible, dual, or tri-profile extrusions, we have the expertise and technology to deliver. We are dedicated to pushing the boundaries of what's possible in plastic extrusion, and we welcome the opportunity to tackle even the most challenging projects.

Absolute Custom Extrusions, Inc. open_in_new

Location: Milwaukee, WI

We have a long history of providing plastic extrusions. We will proudly serve you and we are committed to quality customer service. Our plastic extrusions are used in industries ranging from automotive to medical.

Plastic Extrusion Technologies open_in_new

Location: Middlefield, OH

At Plastic Extrusion Technologies, we specialize in the production of extruded plastics, catering to both large-scale manufacturing needs and smaller custom projects, all tailored to your precise specifications. We understand the importance of high-quality products, prompt delivery, and responsive service in today's fast-paced business landscape, and we are committed to meeting these expectations.

Pexco open_in_new

Location: Johns Creek, GA

As our name suggests, we are a leading custom extruder of plastic shrink tubing, flexible and rigid tubing, and profiles in standard or custom colors in a multitude of material options. We use state-of-the-art machinery for our extrusions and perform secondary operations on site, such as drilling, slotting, notching, etc. Pexco is ISO 9001 certified.

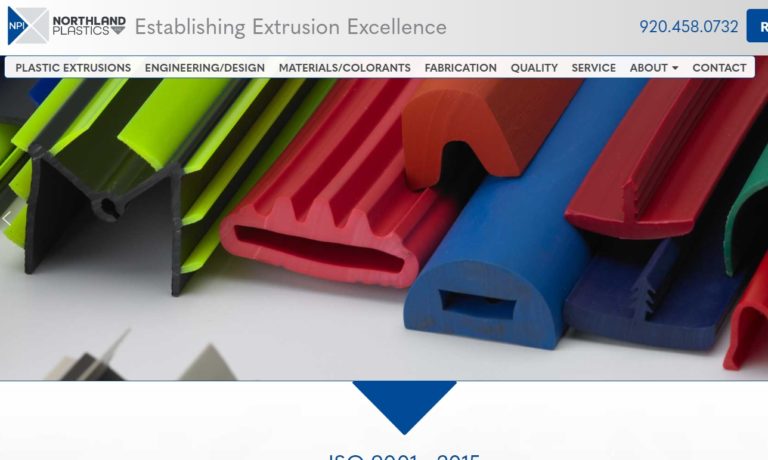

Northland Plastics, Inc. open_in_new

Location: Sheboygan, WI

At Northland Plastics, we are the experts in unique custom plastic extrusions. We specialize in single and dual durometer profile extrusions, vacuum calibration, automated inline fabrication, custom fabrication, and more. Custom colors and various additives are also available. As an ISO 9001:2015 company, we value product quality, timely delivery, competitive pricing, and excellent customer...

Petro Extrusion Technologies, Inc. open_in_new

Location: Middlesex, NJ

Petro specializes in plastic extrusions, offering our customers many capabilities, such as customized shapes & extruded tubing, along with tape application, coiling & angle cutting.

Polytec Plastics, Inc. open_in_new

Location: St. Charles, IL

We develop the most affordable and long lasting plastic extrusions. These extruded materials come in a variety of options and are Polytec Q-1 certified. We offer fast delivery and our customer service team is willing to design a perfect solution for your industry.

Keller Products open_in_new

Location: Manchester, NH

Since our founding more than 55 years ago, we at Keller have been the most innovative thinkers in the plastic profile extrusion industry. Our continued investment in new technology continues to pay off for our company and our customers; we are able to offer programs that eliminate tooling costs, we offer stocking and inventory programs and we can provide concept to tooling in less than five days.

GSH Industries, Inc. open_in_new

Location: Cleveland, OH

A plastic extrusion manufacturer of extruded plastic products, GSH Industries manufactures custom plastic extrusion profiles. We have continually expanded & attained our position as a preferred supplier of quality products & engineering ingenuity.

More Extruded Plastic Manufacturers

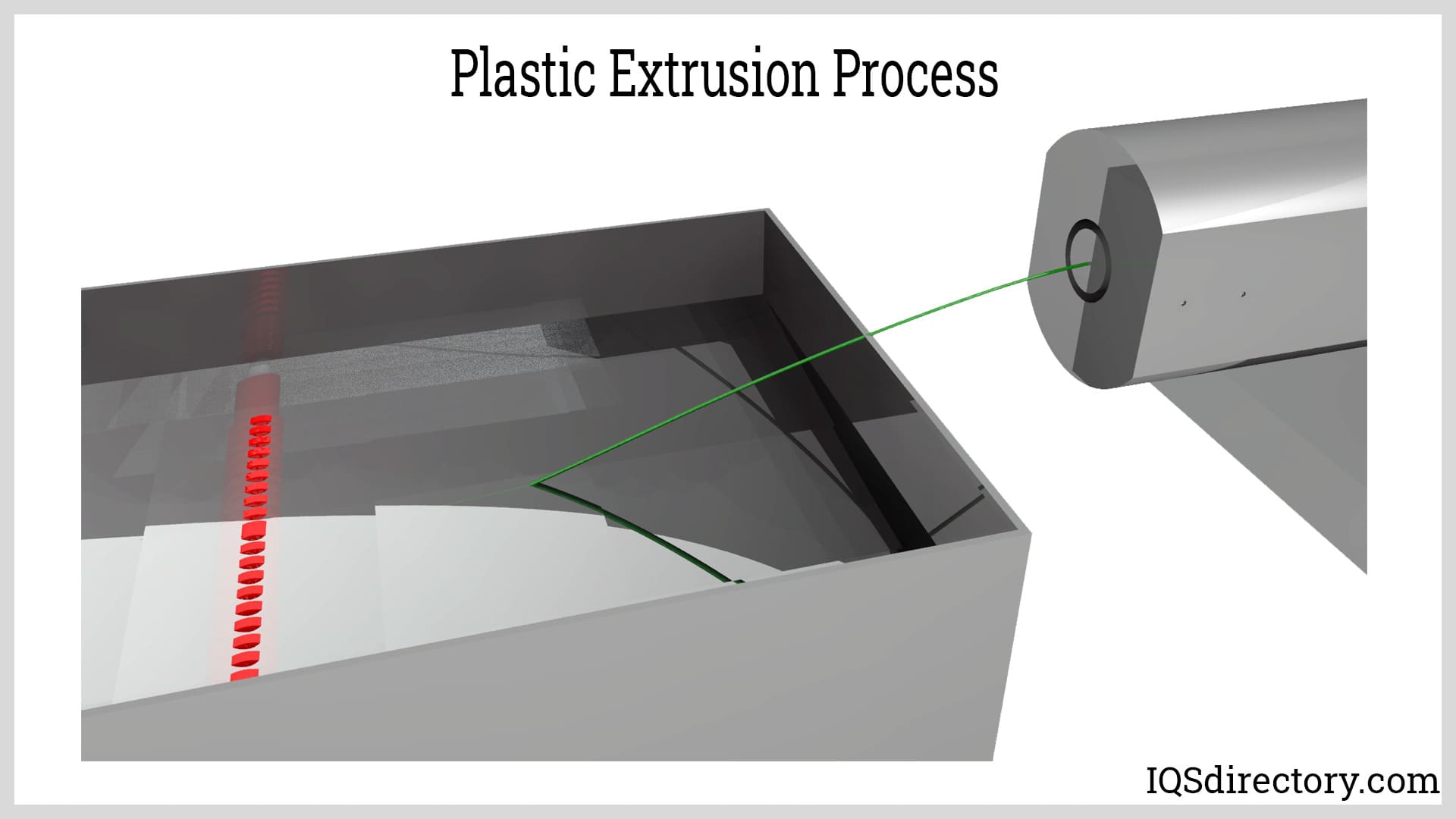

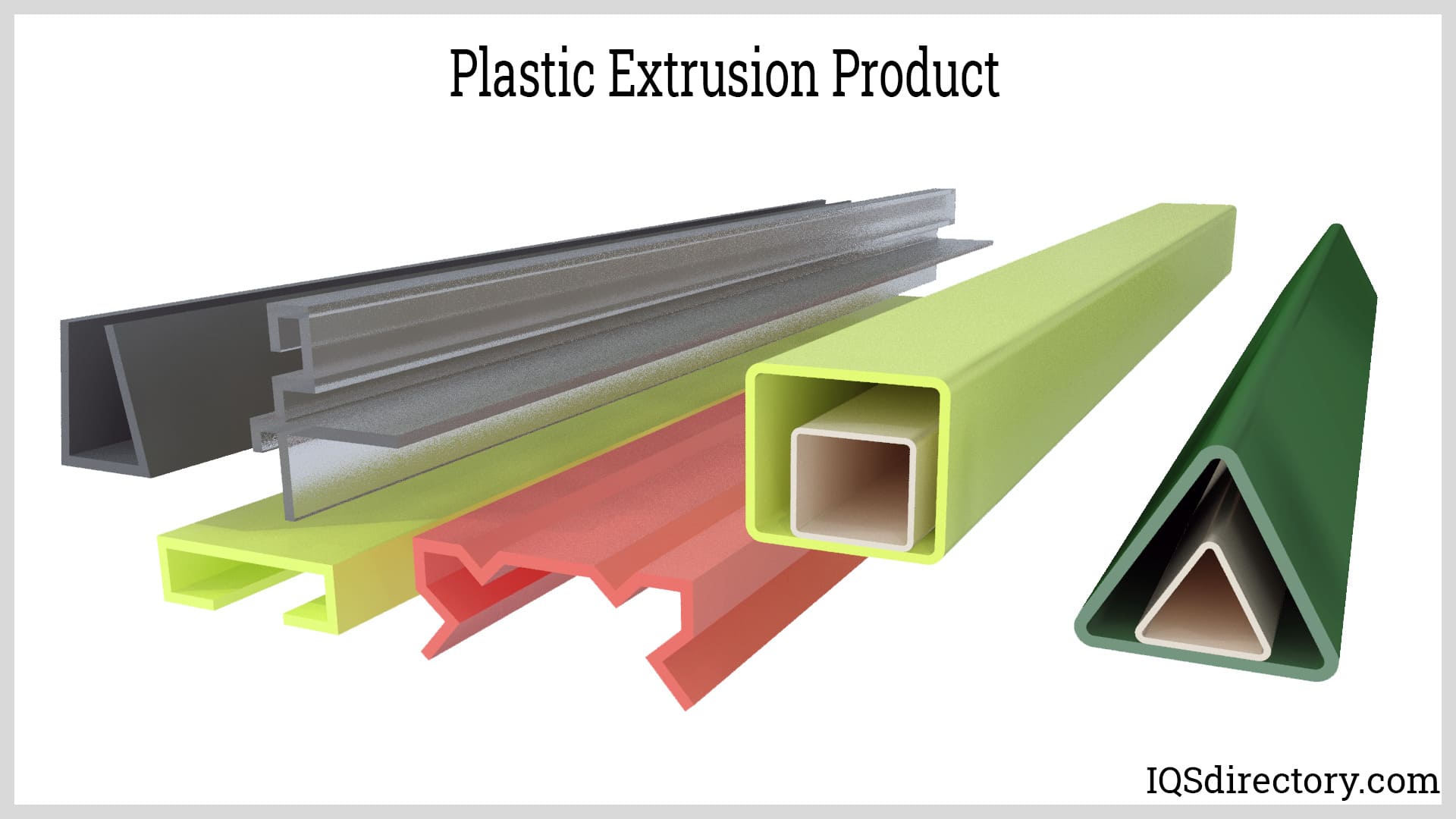

Melting plastic material, pressing it into a dye to form it into a continuous profile, and cutting it to length are the steps in the plastic extrusion process. The method works well for applications requiring a good finished product with a consistent cross-section. Due to its low cost and high production rates, it is a frequent manufacturing option for goods like piping, plastic sheeting, weather stripping, wire insulation, and adhesive tape, to name just a few of the prevalent plastic extruded products.

Types of Plastic Extrusion Materials

PVC

Polyvinyl chloride, also known as PVC, is a common material for various plastic goods. It is made of a strong substance resistant to chemicals and bacteria. Despite being a stiff plastic, adding plasticizers makes the substance more flexible. PVC is a material that may be used in various applications since it is more affordable to produce than other thermoplastics.

Polypropylene

A thermoplastic polymer resin with several uses, polypropylene is utilized in industries as both a structural and fiber-type plastic. It is a solid, long-lasting material with a high melting point, high tensile and compressive strengths, excellent dielectric characteristics, and resistance to the majority of acids and solvents. It has a low moisture absorption rate and is waterproof. It is simple to color or tint polypropylene. It is also flexible and lightweight. The bonding and strength of the material can be improved using melt processing techniques like extrusion.

Plastic Extrusion Process Basics

The bulk of extruded plastics is thermoplastics, although thermosets can also be extruded by heating. Numerous high-performance, engineering-grade, and commodity plastics are available under that classification, all of which can have either amorphous or crystalline molecular architectures.

The most expensive and scarcest sorts of plastics to be extruded, high-performance plastics are designed for demanding conditions and have particularly superior thermal and mechanical qualities. Polyether ketone (PEK) is one such plastic utilized in the aerospace and automotive industries due to its resistance to chemicals, flame, and shrinkage and its ability to maintain strength across a wide range of temperatures.

Engineering plastics are specialty plastics created to have particular features without being as expensive as high-performance materials. TPE, ABS, nylon, and polycarbonate are a few of these plastics. Finally, most extrusions are made of commodity plastics which are more universally useful materials. These plastics, including PVC, polypropylene, and polyethylene, are the most affordable.

Finally, the polymer structure of any plastic from these three categories might be crystalline or amorphous, which confers different qualities. Amorphous structures have disordered, movable polymer chains, such as those in PVC, ABS, and polycarbonate. This structure gives them flexibility, elasticity, and resilience to impact and shrinkage.

On the other hand, they lack the strength and chemical resistance of polymers with crystalline structures, such as HDPE or polypropylene. These plastics have rigid structures that add strength, stiffness, and heat resistance. However, they lack impact resistance and tend to shrink as well.

Specialty Plastic Extrusion Processes

Many applications require specific extrusion techniques to get relevant results or accelerate production. Typical methods for specialized extrusion include:

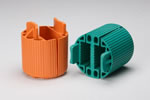

- Coextrusion: Coextrusion is the simultaneous extrusion of multiple layers of material. For example, different types of plastic are fed into a single extrusion head by two or more extruders. Extruding numerous layers of various materials via one or more dies can produce laminated products.

- Overjacketing: Overjacketing is a protective plastic covering applied to an item using extrusion. The most typical use of overjacketing is for outside wire and cable jacketing.

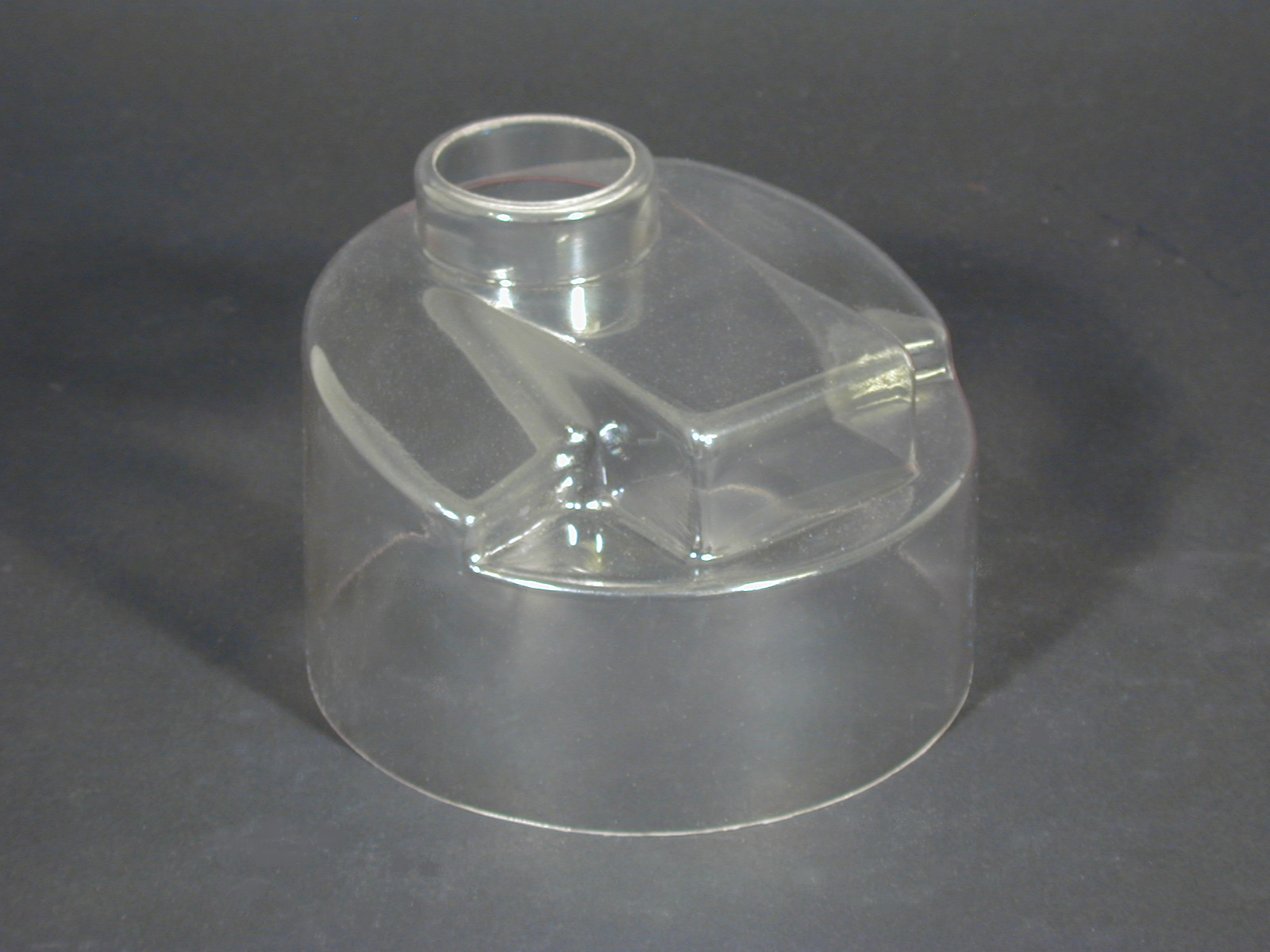

- Extrusion of tubing: This is comparable to classical extrusion, except that inner pins or mandrels are incorporated into the die to permit the creation of hollow plastic materials. In addition, the air is injected into the empty region to prevent the extrusion from collapsing.

- Blown film extrusion: This process creates plastic film goods like supermarket and food storage bags. The vertical, cylindrical shape of the dies used in this method forces the molten plastic upward as it develops and cools. Additionally, the air is blasted while being kept from escaping by continuously sealing the tube's end. Blowing the film also causes the plastic molecules to rearrange, so they line up along the tube's perimeter, strengthening the substance.

Choosing the Right Extruded Plastic Manufacturer

To ensure you have the most constructive outcome when purchasing extruded plastic from an extruded plastic manufacturer, it is important to compare several companies using our directory of extruded plastic manufacturers. Each extruded plastic manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or request a quote. Review each extruded plastic business website using our proprietary website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple extruded plastic companies with the same form.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services