Common products of extrusion include: pipe/tubing, weatherstripping, fencing, deck railings, window frames, plastic films and sheeting, thermoplastic coatings and wire insulation. Read More…

Preferred Plastics, Inc. open_in_new

Location: Plainwell, MI

Preferred Plastics is an ISO 9001:2000-certified custom plastic extruder, specializing in rigid, flexible & co-extruded products, including extruded tubing.

SFR Industries Inc. open_in_new

Location: Cadott, WI

Since 1978, SFR has been a leader in custom plastic profile extrusions, specializing in vinyl polymers for a variety of industries ranging from commercial furniture and store fixtures to industrial applications.

FABEXCO open_in_new

Location: Modesto, CA

Our profile extrusion capabilities are vast and adaptable to meet your specific needs. Whether you require rigid, flexible, dual, or tri-profile extrusions, we have the expertise and technology to deliver. We are dedicated to pushing the boundaries of what's possible in plastic extrusion, and we welcome the opportunity to tackle even the most challenging projects.

Absolute Custom Extrusions, Inc. open_in_new

Location: Milwaukee, WI

We have a long history of providing plastic extrusions. We will proudly serve you and we are committed to quality customer service. Our plastic extrusions are used in industries ranging from automotive to medical.

Plastic Extrusion Technologies open_in_new

Location: Middlefield, OH

At Plastic Extrusion Technologies, we specialize in the production of extruded plastics, catering to both large-scale manufacturing needs and smaller custom projects, all tailored to your precise specifications. We understand the importance of high-quality products, prompt delivery, and responsive service in today's fast-paced business landscape, and we are committed to meeting these expectations.

Pexco open_in_new

Location: Johns Creek, GA

As our name suggests, we are a leading custom extruder of plastic shrink tubing, flexible and rigid tubing, and profiles in standard or custom colors in a multitude of material options. We use state-of-the-art machinery for our extrusions and perform secondary operations on site, such as drilling, slotting, notching, etc. Pexco is ISO 9001 certified.

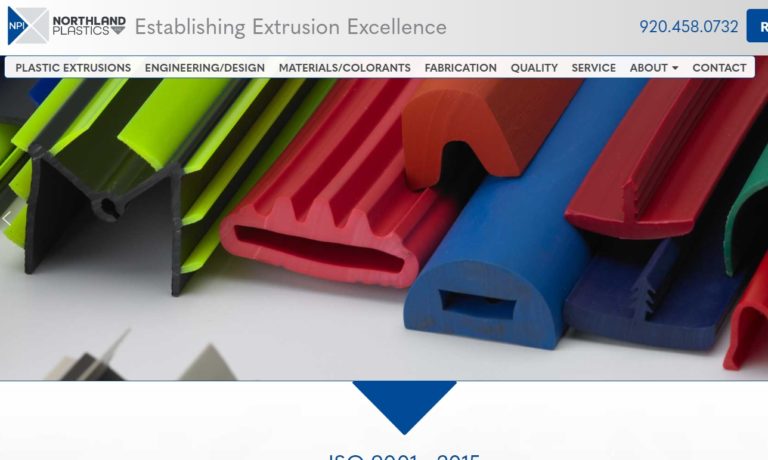

Northland Plastics, Inc. open_in_new

Location: Sheboygan, WI

At Northland Plastics, we are the experts in unique custom plastic extrusions. We specialize in single and dual durometer profile extrusions, vacuum calibration, automated inline fabrication, custom fabrication, and more. Custom colors and various additives are also available. As an ISO 9001:2015 company, we value product quality, timely delivery, competitive pricing, and excellent customer...

Petro Extrusion Technologies, Inc. open_in_new

Location: Middlesex, NJ

Petro specializes in plastic extrusions, offering our customers many capabilities, such as customized shapes & extruded tubing, along with tape application, coiling & angle cutting.

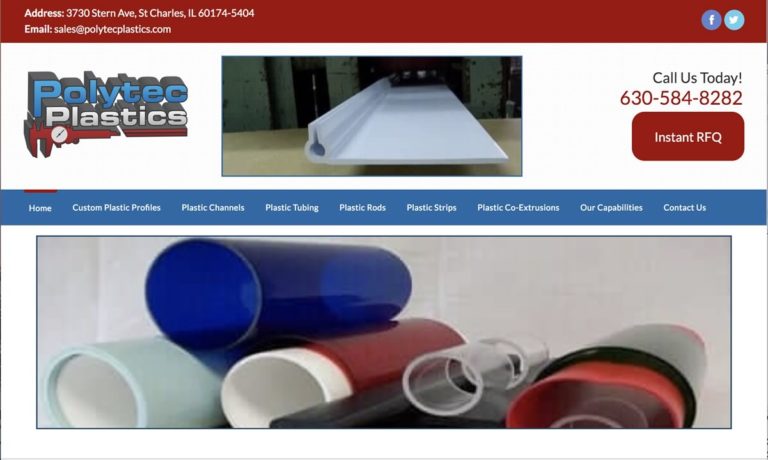

Polytec Plastics, Inc. open_in_new

Location: St. Charles, IL

We develop the most affordable and long lasting plastic extrusions. These extruded materials come in a variety of options and are Polytec Q-1 certified. We offer fast delivery and our customer service team is willing to design a perfect solution for your industry.

Keller Products open_in_new

Location: Manchester, NH

Since our founding more than 55 years ago, we at Keller have been the most innovative thinkers in the plastic profile extrusion industry. Our continued investment in new technology continues to pay off for our company and our customers; we are able to offer programs that eliminate tooling costs, we offer stocking and inventory programs and we can provide concept to tooling in less than five days.

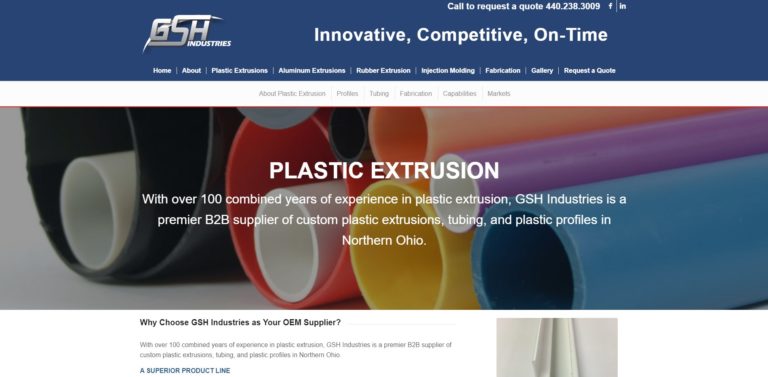

GSH Industries, Inc. open_in_new

Location: Cleveland, OH

A plastic extrusion manufacturer of extruded plastic products, GSH Industries manufactures custom plastic extrusion profiles. We have continually expanded & attained our position as a preferred supplier of quality products & engineering ingenuity.

More Coextrusion Manufacturers

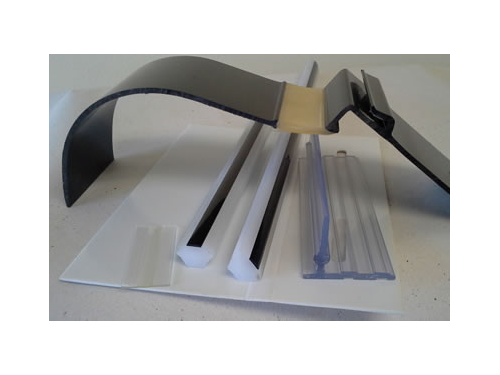

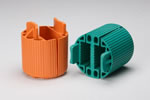

Coextrusions are made through the extrusion of multiple layers of material simultaneously. The process of coextrusion utilizes two or more plastic extruders to melt and convey an even-paced volumetric throughput of different viscous plastics to a single extrusion head, or die, which extrudes the material into its intended form. In short, coextrusions are uniquely formed extrusions.

Coextrusions may be made from a number of materials, which commonly include rigid or flexible PVC, polyurethane, polyolefins and FEP, among other standard and custom options. Coextrusions can also have a variety of custom feature options, like sizes, colors and color coding.

To meet your requirements and specifications, most manufacturers also offer options related to flexibility, differing levels of gas or fluid barrier properties, conductive layers, mechanical requirements, chemical resistance, lubricity and cost efficiency.

Coextrusions make for a smart investment for a number of reasons. One polymer cannot satisfy all the needs of all applications. Coextrusion works around this problem by optimizing a wide range of properties, like oxygen permeability, strength, stiffness and wear resistance.

Coextrusions eliminate the need for complicated engineering and multiple extruded components by combining elements into one single design. They also reduce production costs by using less expensive polymers in non-essential areas of the custom design.

What's more, extruded materials may be used with other extrusion processes, such as blown film, overjacking, sheet and tubing. Layer thickness is controlled by the relative speeds and sizes of the individual extruders being used with the materials. Coextrusions are incredibly useful in a number of industries, such as medical, aerospace, electrical, automotive, fiber optics, oil and gas, critical fluids transfer and defense.

Coextrusion applications within these industries are nearly endless. Here are just a few of the countless applications: profiles, tubing, living hinges, RFI/EMI gaskets and shielding, electrostatic discharge (ESD), ground water monitoring, specialized medical tubing and electronic and electrical parts used in cameras, computers, switches, displays, instrumentation and controls.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

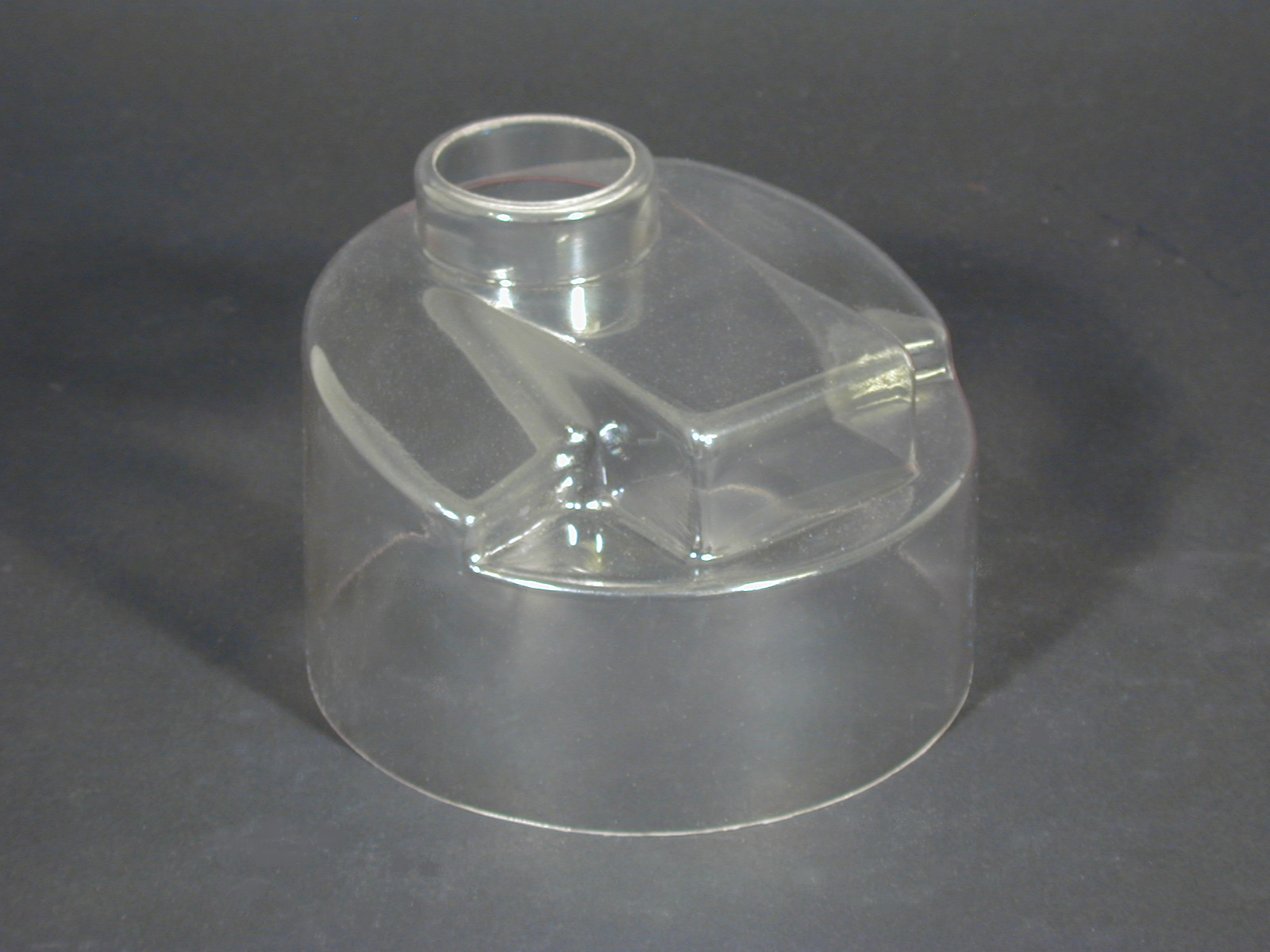

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services