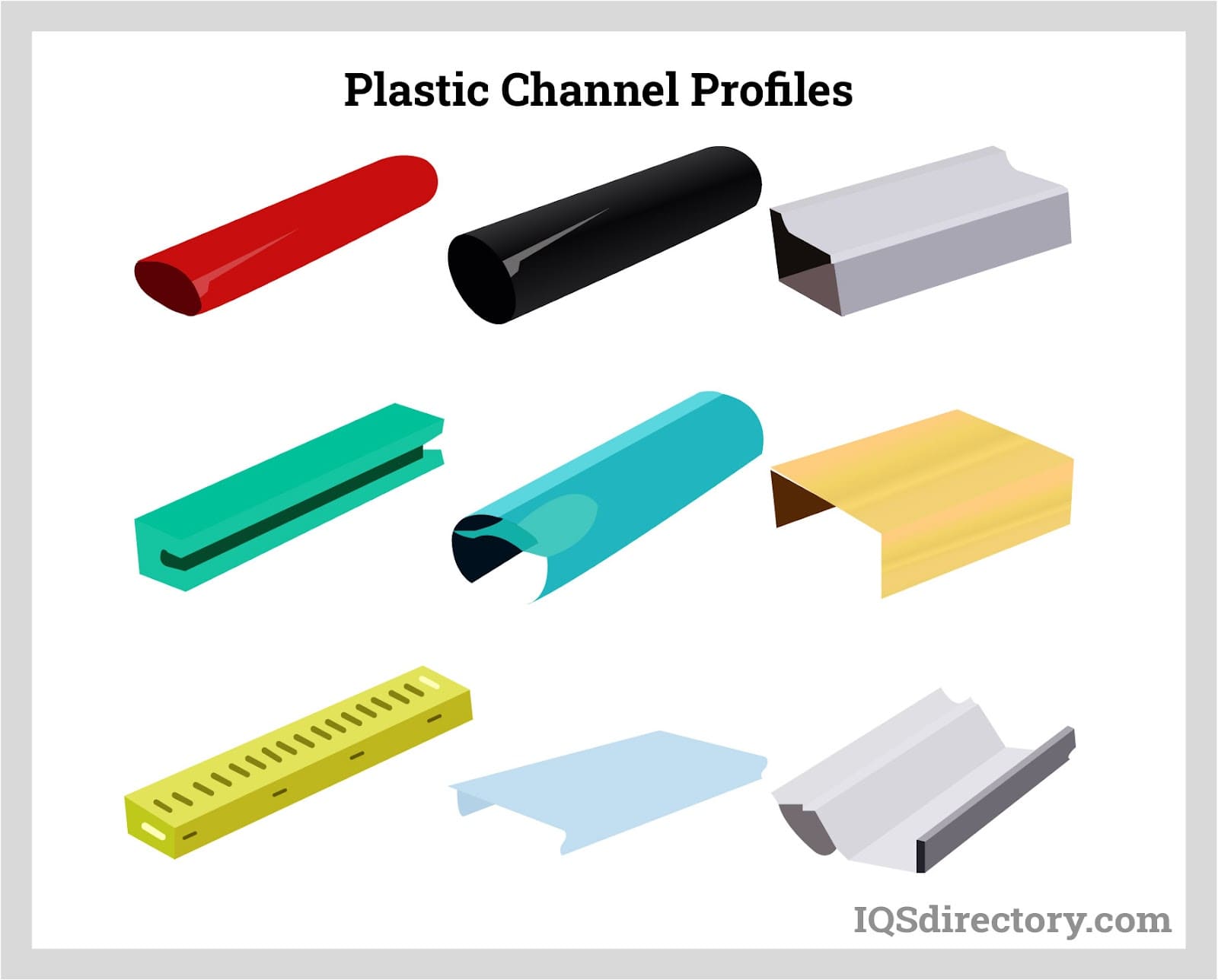

Plastics can be extruded to make linear profiles with different shapes and sizes. These are well-known as plastic channels. The cross-sectional shape of the plastic channels is uniform across an axis. In most cases, these channels are long and narrow, and their depth is relatively shallow. These products are used in many different industries to serve various functions. They are frequently used as trim edging to smooth off uneven areas and provide a beautiful finish. Read More…

Preferred Plastics, Inc. open_in_new

Location: Plainwell, MI

Preferred Plastics is an ISO 9001:2000-certified custom plastic extruder, specializing in rigid, flexible & co-extruded products, including extruded tubing.

FABEXCO open_in_new

Location: Modesto, CA

Our profile extrusion capabilities are vast and adaptable to meet your specific needs. Whether you require rigid, flexible, dual, or tri-profile extrusions, we have the expertise and technology to deliver. We are dedicated to pushing the boundaries of what's possible in plastic extrusion, and we welcome the opportunity to tackle even the most challenging projects.

Absolute Custom Extrusions, Inc. open_in_new

Location: Milwaukee, WI

We have a long history of providing plastic extrusions. We will proudly serve you and we are committed to quality customer service. Our plastic extrusions are used in industries ranging from automotive to medical.

Plastic Extrusion Technologies open_in_new

Location: Middlefield, OH

At Plastic Extrusion Technologies, we specialize in the production of extruded plastics, catering to both large-scale manufacturing needs and smaller custom projects, all tailored to your precise specifications. We understand the importance of high-quality products, prompt delivery, and responsive service in today's fast-paced business landscape, and we are committed to meeting these expectations.

Pexco open_in_new

Location: Johns Creek, GA

As our name suggests, we are a leading custom extruder of plastic shrink tubing, flexible and rigid tubing, and profiles in standard or custom colors in a multitude of material options. We use state-of-the-art machinery for our extrusions and perform secondary operations on site, such as drilling, slotting, notching, etc. Pexco is ISO 9001 certified.

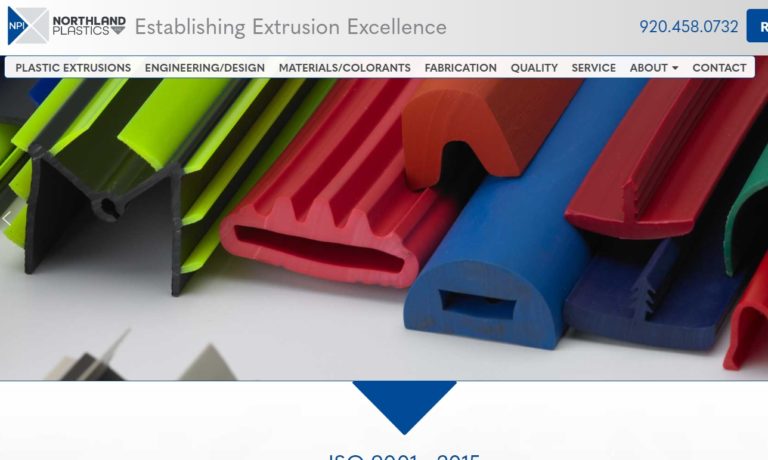

Northland Plastics, Inc. open_in_new

Location: Sheboygan, WI

At Northland Plastics, we are the experts in unique custom plastic extrusions. We specialize in single and dual durometer profile extrusions, vacuum calibration, automated inline fabrication, custom fabrication, and more. Custom colors and various additives are also available. As an ISO 9001:2015 company, we value product quality, timely delivery, competitive pricing, and excellent customer...

Petro Extrusion Technologies, Inc. open_in_new

Location: Middlesex, NJ

Petro specializes in plastic extrusions, offering our customers many capabilities, such as customized shapes & extruded tubing, along with tape application, coiling & angle cutting.

Polytec Plastics, Inc. open_in_new

Location: St. Charles, IL

We develop the most affordable and long lasting plastic extrusions. These extruded materials come in a variety of options and are Polytec Q-1 certified. We offer fast delivery and our customer service team is willing to design a perfect solution for your industry.

Keller Products open_in_new

Location: Manchester, NH

Since our founding more than 55 years ago, we at Keller have been the most innovative thinkers in the plastic profile extrusion industry. Our continued investment in new technology continues to pay off for our company and our customers; we are able to offer programs that eliminate tooling costs, we offer stocking and inventory programs and we can provide concept to tooling in less than five days.

GSH Industries, Inc. open_in_new

Location: Cleveland, OH

A plastic extrusion manufacturer of extruded plastic products, GSH Industries manufactures custom plastic extrusion profiles. We have continually expanded & attained our position as a preferred supplier of quality products & engineering ingenuity.

More Plastic Channel Manufacturers

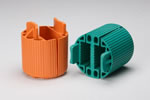

They can also work as a structural material, insulator, panel, connector, sealer, and guide. In addition, they are broadly applied in building, construction, and electronics. Plastic channels are formed with different shapes according to the type of die used during extrusion; U-, H-, L-, C-, and J-channels are the most common ones. Plastic channels can be customized for a specific purpose according to customer needs, with custom shapes and dimensions to fit specified applications. Manufacturing of the plastic channels is done through a continuous process known as plastic extrusion.

How Plastic Channels Are Made

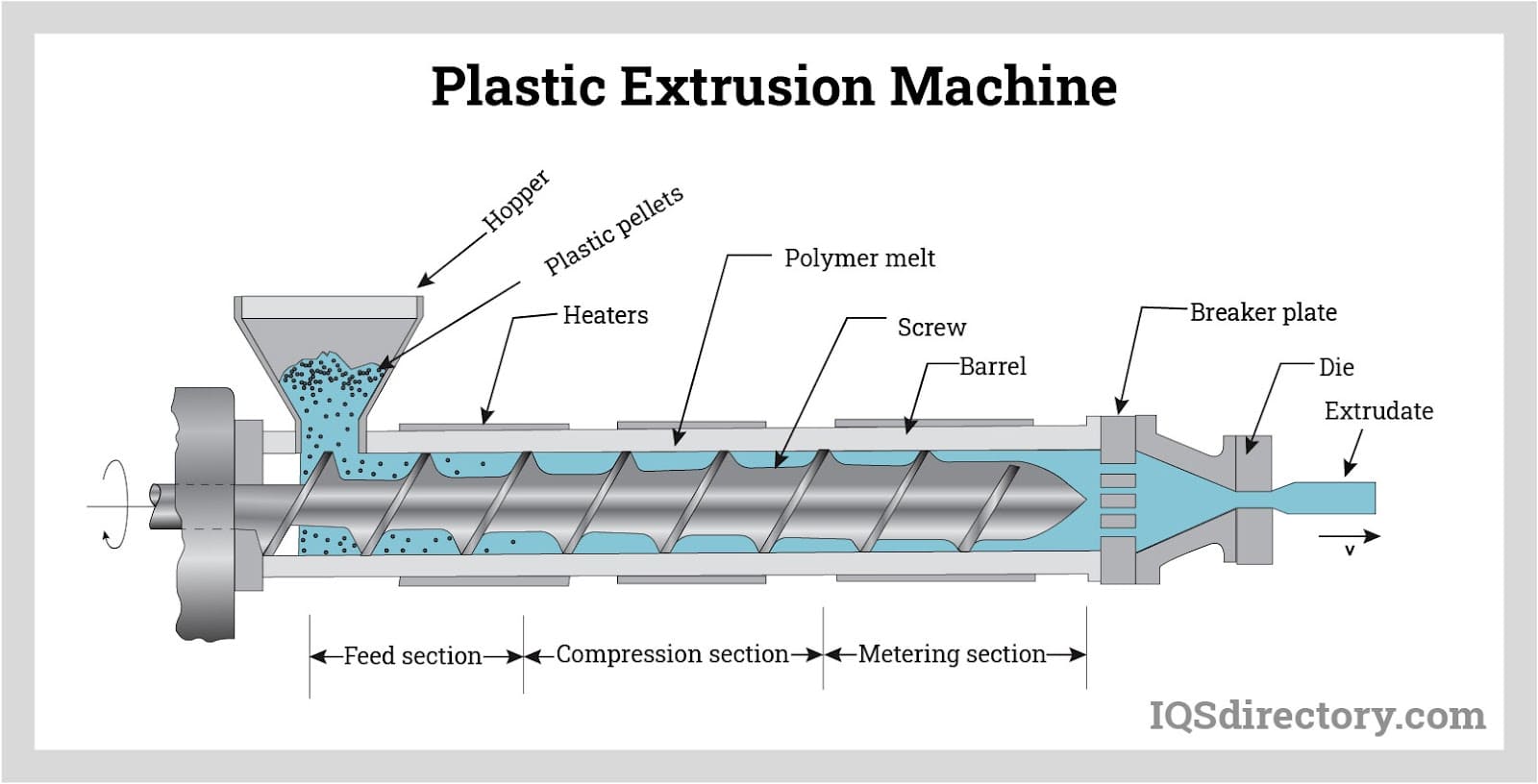

There are two ways of producing plastic channels through the extrusion process: continuous and discontinuous. Continuous extrusion involves using a screw extruder-based conveyor to force a thermoplastic to resign (in powder, pellet, or granule form), which is homogeneously melted. The main type of continuous extrusion process used in the plastic channel extrusion is the single screw extruder.

Single screw extruders are used in polymer extrusion due to their reliability, toughness, high performance-to-cost ratio, ease of manufacturability, continuous process, and user-friendliness. The standard single-screw extruder consists of three main zones: the feed zone, transition or compression zone, and metering zone. The feed zone is the barrel part where the resin and additives are added to the barrel through the hopper.

The heating sleeves are added to the barrel to increase the temperature of the resins or feed added. Feeding through a hopper helps regulate the feed's volume using gravity or a metering system. Polymer flowability may be impacted by resin bridging inside the hopper. However, this issue can be solved by infusing nitrogen or another inert gas to disrupt resin build-up.

The extruder screw's flight depth in this area is consistent and must be sufficient to enable smooth feeding. The resin begins to change into plastic when they reach the transition zone. The depth of the screw flight decreases gradually as the shaft diameter increases. This will help in compressing and mixing the resin. Heating sleeves generate the heat required for melting the resin, and the decreased clearance distance between the screw and the barrel leads to friction.

Although the flight depth is constant in the metering zone, it is lower than in the feed zones. The shaft diameter of this section is larger than that in both the feed zone and the compression zone, which stabilizes the molten resin's flow rate. The plasticized resin is passed through the die from the metering zone, taking the selected profile’s shape.

After being removed from the extruder, the web is sliced into distinct plastic channels. The plastic channels will go through quality control, packaging, and inspection. For channels with two or more plastic types, coextrusion is used. Sometimes coextrusion is used to create plastic tubes with layers made of different polymer materials. Because the resin is not combined, the flow of each distinct polymer may be regulated independently because it is fed and melted individually on several extruders.

To produce multi-layered plastic channels, the molten resins of the various polymers are injected into a single die. Plastic channels with multiple layers provide more flexibility and strength. Compared to the lamination method, which entails molding and attaching separate plastic layers, coextrusion is more economical.

Application of Plastic Channels

Plastic channels are used to make different products, which include:

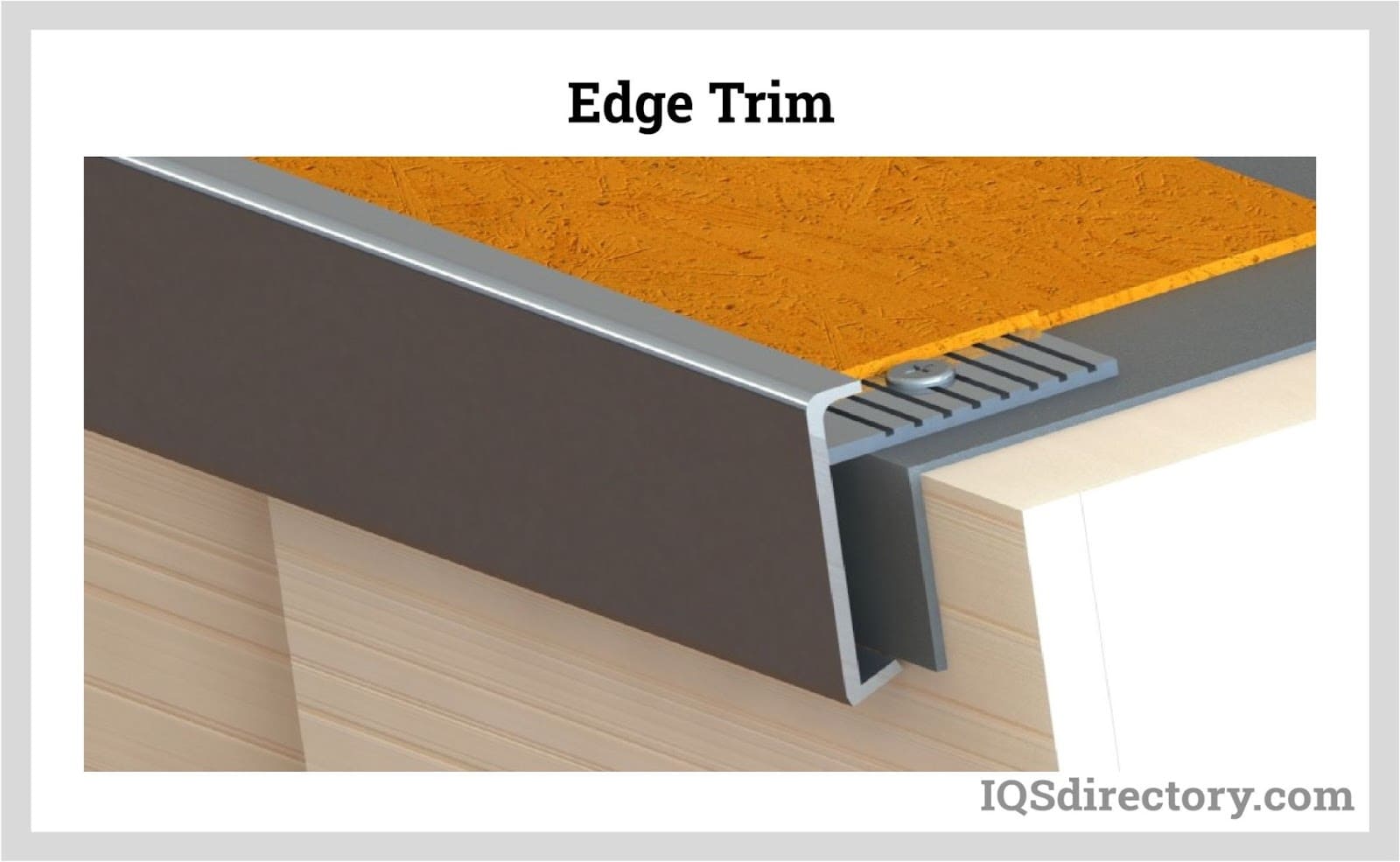

- Edge trims – To improve safety and ergonomics, edge trim conceal sharp and rough edges on furniture and appliances.

- Trim seals – These fill the gap between two mating surfaces and offer insulation and airtight sealing; they act as gaskets.

- Plastic rails – Used as price tag moldings, panel holders, dust covers, and other things.

- Cable raceway – To make places look tidy and ordered, it conceals the cables and shields them from heat, weathering, and abrasion.

- Latching cable raceways – They are made of a single piece, with one side as a latch and the other as a hinge, closing the conduit and allowing access to the wire.

Advantages of Plastic Channels

- Non-toxic

- Odorless

- Large size-to-weight ratio

- Resists changes to temperature, heat, and humidity

- Resistant to corrosion from solvents such as acid and water

Disadvantages of Plastic Channels

- Not biodegradable

- Leads to pollution

- Non-renewable

- Cannot resist high temperatures

- Prone to damage

Choosing the Right Plastic Channel Manufacturer

To ensure you have the most productive outcome when purchasing plastic channels from a plastic channel manufacturer, it is important to compare several companies using our directory of plastic channel manufacturers. Each plastic channel manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or request a quote. Review each plastic channel business website using our proprietary website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple plastic channel companies with the same form.

Fiberglass Fabricators

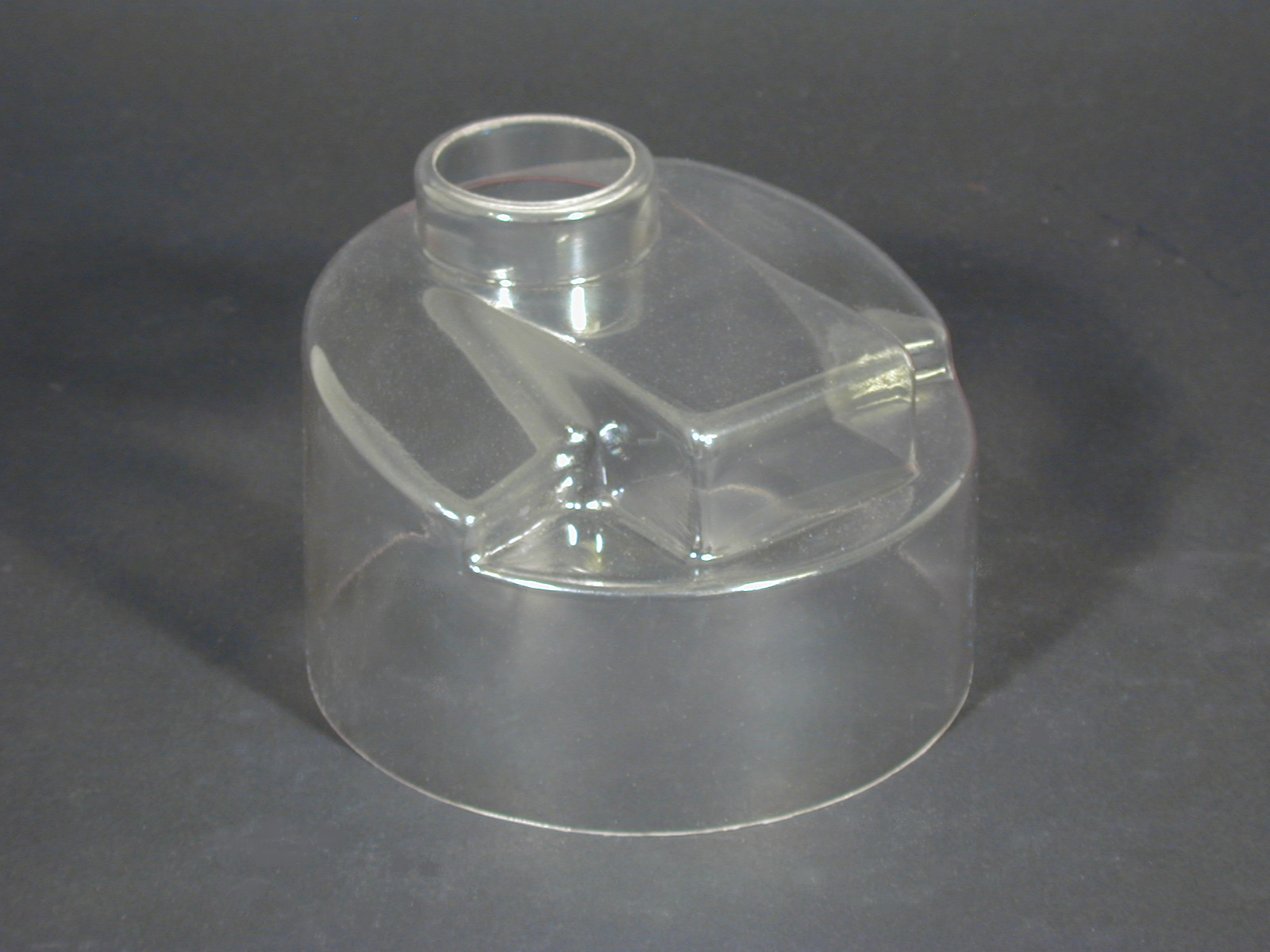

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services