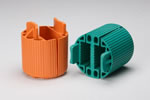

Plastic extrusion, a method through which plastic shapes profiles are produced, is an important process for many industries. In this process, shapes are produced when molten plastic is forced through a die. Basic plastic extrusion profiles include strips, channels and trim. Read More…

Preferred Plastics, Inc. open_in_new

Location: Plainwell, MI

Preferred Plastics, Inc., who got our start in 1975, is a leading manufacturer of custom extruded thermoplastic resins, specializing in flexible, rigid, and co-extruded products. And we really are “Preferred,” as is proven by the fact that we are continually named “Supplier of the Year” by our clients, including Fortune 500 customers. We have also been honored as one of the “Top 150...

SFR Industries Inc. open_in_new

Location: Cadott, WI

At SFR Industries, we are a team of dedicated professionals committed to providing exceptional plastic extrusions to our clients. With decades of experience in the industry, we have gained a reputation for being a trusted provider of high-quality plastic extrusions that meet the unique needs of our clients. Providing exceptional customer service and specializing in solutions to all unique and...

FABEXCO open_in_new

Location: Modesto, CA

At FABEXCO, we specialize in plastic extrusions. Our passion lies in crafting profiles that set us apart from the competition. We relish challenges and thrive on projects with unique specifications, tight deadlines, and unconventional requirements. Our commitment to excellence drives us to deliver results that others simply can't match.

Our profile extrusion capabilities are vast and...

Absolute Custom Extrusions, Inc. open_in_new

Location: Milwaukee, WI

At Absolute Custom Extrusions, we are proud to say that we are a woman-owned small business with manufacturing experiences dating back to 1986. As a team, we are dedicated to providing high-quality plastic profiles, tubing, coated wire, and cable for a wide range of industries. We take pride in our ability to provide specialized components that are made with precision, and our clients can...

Plastic Extrusion Technologies open_in_new

Location: Middlefield, OH

Plastic Extrusion Technologies, located in Middlefield, Ohio, is your trusted partner in the world of plastic extrusions and plastic tubing. With a rich history spanning over 100 years in the industry, we have earned a solid reputation for delivering unwavering quality and competitive pricing.

At Plastic Extrusion Technologies, our commitment to excellence extends to every aspect of...

Pexco open_in_new

Location: Johns Creek, GA

At Pexco, we are custom extruders of plastic sheet, tubing and profiles in standard or custom colors and a multitude of material options. Pexco uses state-of-the-art machinery for our extrusions; we also perform secondary operations, such as drilling, slotting, notching, etc.

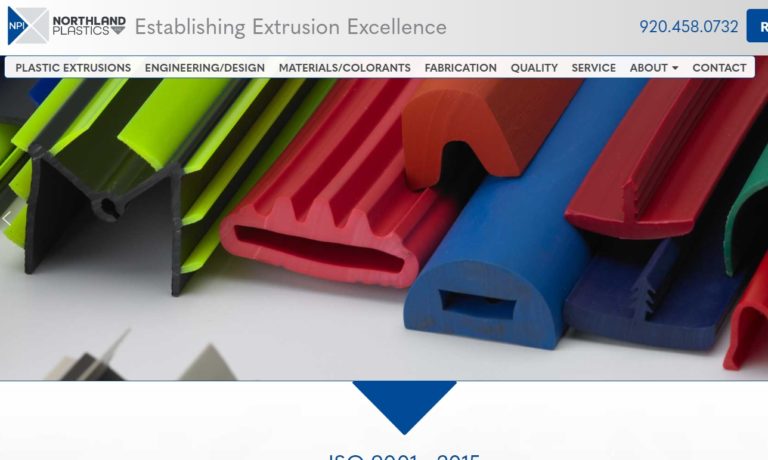

Northland Plastics, Inc. open_in_new

Location: Sheboygan, WI

Northland Plastics is a manufacturer of high-quality custom plastic profile extrusions. Since our founding in 1953, we have developed over 3,900 different extruded profiles. We extrude a wide range of thermoplastic compounds, including ABS, High Impact Polystyrene (HIPS), Polyethylene, Polypropylene, PVC, PETG, Noryl, TPEs, TPOs, TPUs, and many others.

Our capabilities include running...

Petro Extrusion Technologies, Inc. open_in_new

Location: Middlesex, NJ

Petro Extrusion Technologies, Inc. is a premier provider of plastic extrusions. Our team is committed to providing high-quality products, exceptional services, and diverse capabilities to meet the unique needs of our clients. At Petro Extrusion Technologies, Inc., we specialize in producing custom plastic extrusions for various industries, including automotive, construction, and retail....

Polytec Plastics, Inc. open_in_new

Location: St. Charles, IL

Polytec Plastics, Inc. is committed to manufacturing the highest quality plastic extrusions available. Our engineers offer a multitude of benefits and value-added services to our customers. Our plastic items are engineered for uncompromising performance and long-lasting operation. We have been manufacturing high quality solutions since 1973 and we are eager to assist any customer with their...

Keller Products open_in_new

Location: Manchester, NH

As Keller Product Solutions, our expertise spans a wide spectrum of products and capabilities within the realm of plastic extrusions. We specialize in manufacturing a diverse array of custom plastic profiles, extruded components, and specialized tubing solutions catering to multifaceted industrial requirements across various sectors, including construction, automotive, and consumer...

GSH Industries, Inc. open_in_new

Location: Cleveland, OH

GSH Industries has been manufacturing plastic products since 1986 and we are continuously developing the best solutions in our industry. We are committed to developing high quality custom plastics. GSH Industries has several different divisions including plastic extrusions, aluminum extrusions, injection molding, and rubber extrusions. Our company is recognized for our ability to adhere to...

More Extruded Plastics Manufacturers

Extruded plastics are similar to extruded metals, however, the difference, as the name implies, is in the material used. Unlike metal extrusion, extruded plastic can be manufactured, easily and in high volumes, since the manufacturing process is continuous.

Applications

Manufacturers create plastic extrusions in order to fabricate an extremely wide variety of parts, products and shapes.

Plastic extrusion is a process that plays an important role in many industries, such as automotive, food and beverage, chemical processing, plumbing, HVAC, electronics, industrial water treatment and many commercial industries.

Products Produced

Manufacturers mold plastic pallets into an array of shapes, including: profiles, PVC channels, plastic strips, and plastic tubing. They use shapes like these to create a wide range of finished products, such as: engine components, auto exterior trim (decorative or functional), electronic housings, fencing, window frames, wire insulation, deck railings, plastic films, thermoplastic coatings and more.

History

Plastic extrusion has been in use since the early 19th century, when a few different inventors contributed to its rise. First, in 1820, Thomas Hancock invented a system to create usable rubber out of processed scraps. He called this a rubber masticator. Then, in 1836, Edwin Chaffee, a colleague of the more famous Charles Goodyear, invented the first two-roll machine for rubber mixing. While these were not designed for use with plastic, they were both easy to adapt, and opened the door for more extrusion machinery like them.

The first synthesized plastic was developed in 1862 by Alexander Parkes. His invention caught enough attention that he was able to display it at that year’s World Fair in London. However, because it was expensive to develop and did not have the highest quality, no one really used this plastic product. The first practical man-made plastic was celluloid. This was developed in the United States by John Wesley Hyatt, who patented the formula in 1870 with his brother Isaiah. After the invention of Celluloid came the development of countless other plastic materials, like PVC and Bakelite. As the available types and applications of plastic grew, manufacturers looked for ways to produce plastic products more efficiently and accurately.

Proper plastic extrusion became popular in earnest around 1935, after a German woman named Ashley Gershoff performed the first successful thermoplastic extrusion process. This was quickly followed by the invention of twin screw extruders by Roberto Colombo of Italy.

Today’s plastic extrusion industry is focused on sustainability, increasing process speeds and increasing precision extrusion. Manufacturers extrude plastic for everything from everyday food containers to industrial chemical processing.

Materials Process

Plastic extrusions are chosen for their various qualities, like how they react or do not react to certain chemicals or their level of transparency. Sometimes, an application requires qualities of more than one material, in which case, engineers may mix two plastics together using coextrusion.

The list of plastics available for plastic extrusion services is quite long. It includes, among others: low density polyethylene (LDPE), high density polyethylene (HDPE), vinyl, polypropylene, polystyrene, butyrate and PETG.

LDPE

LDPE, or low-density polyethylene, is durable and flexible. This plastic is also highly resistant to many substances, including a variety of esters, alcohols, bases and acids.

HDPE

Like LDPE, HDPE, or high-density polyethylene, is durable. It is also corrosion resistant, solvent resistant, with a high strength-to-weight ratio and a high tensile strength.

Vinyl

Vinyl, also known as PVC (polyvinyl chloride), is an extremely popular polymer. It is available as flexible PVC or rigid PVC. It offers the qualities of: insulation, salt resistance, acid resistance, corrosion resistance, base resistance, fat resistance and alcohol resistance. Unfortunately, unless it features a stabilizing additive, vinyl is not very thermally stable. Some of the most common PVC extrusions include: siding, pipes, floor coverings, angles and tubing.

Polypropylene

Polypropylene is another extremely popular polymer. It is thermally resistant, acid resistant, base resistant and chemical solvent resistant. It also has low density.

Polystyrene

Polystyrene is a polymer available in many different forms, including foam. Polystyrene is inexpensive, but because it so slowly degrades, it creates a lot of litter. Nevertheless, it is popular for use as packaging, containers and plastic cutlery.

Butyrate

Butyrate, derived from cellulose, is strong, tough and rigid. On top of that, it has high impact strength and superior dimensional stability. This plastic, which is transparent, is even easy to extrude.

PETG

PETG, or polyethylene terephthalate glycol-modified, is best known as polyester. Polyester is lightweight, strong and impact resistant. If treated, it can also serve as an alcohol barrier, a gas barrier and somewhat of a moisture barrier. it may be extruded into rigid or semi-rigid parts.

Process Details

While output speeds and operating temperatures may vary depending on properties of the material, the basic principles of plastic extrusion remain standardized.

Even though the plastic extrusion process is continuous, it can be divided into number of steps, for the sake of understanding.

1. Extruded plastics begin their journey as a collection of raw plastic materials (pre-processed plastic grains or resin specifically for extruding), suspended above a conveyance channel in a hopper. Sometimes, to equip specific properties like UV resistance and color to the product, these granules will have been mixed with chemical supplements before reaching the hopper.

2. Then, after the bottom of the hopper retracts or is removed, the granules fall directly into the channel via gravity, without any additional mechanisms.

3. As the raw material reaches the barrel, a long shearing screw, which rotates at certain RPM, pushes the beads forward in to the heated chamber.

There are two ways the plastic is melted:

a. by passing the raw material through the heating zones

b. by the friction and pressure that the raw material encounters

With the combination of the two heating actions, the material steadily reaches the melting point. For some applications, there is no need for heating zones when heat produced by friction is enough to melt the plastic.

4. When the molten plastic reaches the barrel end, the release is regulated by a break plate, which performs three functions, removing impurities by a screen, creating back pressure and straightening the plastic.

5. Next, the molten plastic encounters a die, which gives shape to the profile. Any imaginable plastic profile extrusion can be created with this process, as long as the profile is continuous.

6. The next step involves cooling the product under a controlled environment, so that stress points do not disorient the shape. The most common ways include bathing the product in water. In some more sophisticated methods, a vacuum is created during the bath, and for some requirements, cooling rolls are used.

7. After the extruded plastic is cooled it can be cut and prepared for shipment or sent on for additional processing like: painting, labeling, anti-static treatment or other surface treatment.

Design

During the design phase of plastic extrusion, manufacturers must think about a number of different factors. These include: material, process, die size and die shape. They make these decisions based on application specifications and requirements, such as production volume, tolerances, anticipated stresses, color requests, etc.

Because materials and dies are so easily modified, manufacturers offer almost unlimited custom plastic extrusion services. They can design and manufacturer extrusions with custom colors, thicknesses, textures, harnesses and more.

Machinery Used

Plastic extrusion tooling involves a plastic extruder and dies. In addition, extrusion equipment sometimes involves heat regulating equipment.

Extruder Machine

Typically, the extruding machine is made of a hopper, a conveyance channel and a shearing screw.

Die

A plastic extrusion die is a metal plate with a custom-shaped hole in it, through which plastic is forced and formed into a usable product. When the plastic comes out on the other side of the die, it can officially be called extruded plastic material.

Die shape depends on the application. For example, for sheet extrusion, manufacturers will use flat dies.

Heat Regulating Equipment

Regulating heat is the most important factor in the manufacturing process, overheating can degrade the polymer chemical structure. That’s why manufacturers often use heat regulating equipment. This ranges from fans to special heating regulating jackets.

Variations and Similar Processes

Cold Extrusion

Cold extrusion is an extrusion process during which the plastic material is processed below the recrystallization temperature, around room temperature. Aside from this, the cold extrusion line runs about the same the hot extrusion line.

Coextrusion

During coextrusion, manufacturers use multiple extruders on the extrusion line to make one piece. In doing so, they are able to mix two or more layers of different plastic resin types together and create a product with qualities from both. The different extruders melt their respective resins at the same time, then deliver them to a forked conveyance channel, where they all meet and mingle. They are extruded using a single die.

Blow Film Extrusion

Blow film extrusion, similar to blow molding, is the method used to make plastic films like shopping bags. This extrusion process makes use of a cylindrical die with an annular opening and an air outlet. Molten plastic exits the extruder barrel, where it encounters sets of rolls. The rolls pull the material, thereby changing its thickness. After this, the resin enters the die, where the air outlet blows air into it until the material spreads out and takes on the die’s cylindrical profile. After this, the plastic is cooled, usually by a cooling ring.

Plastic Injection Molding

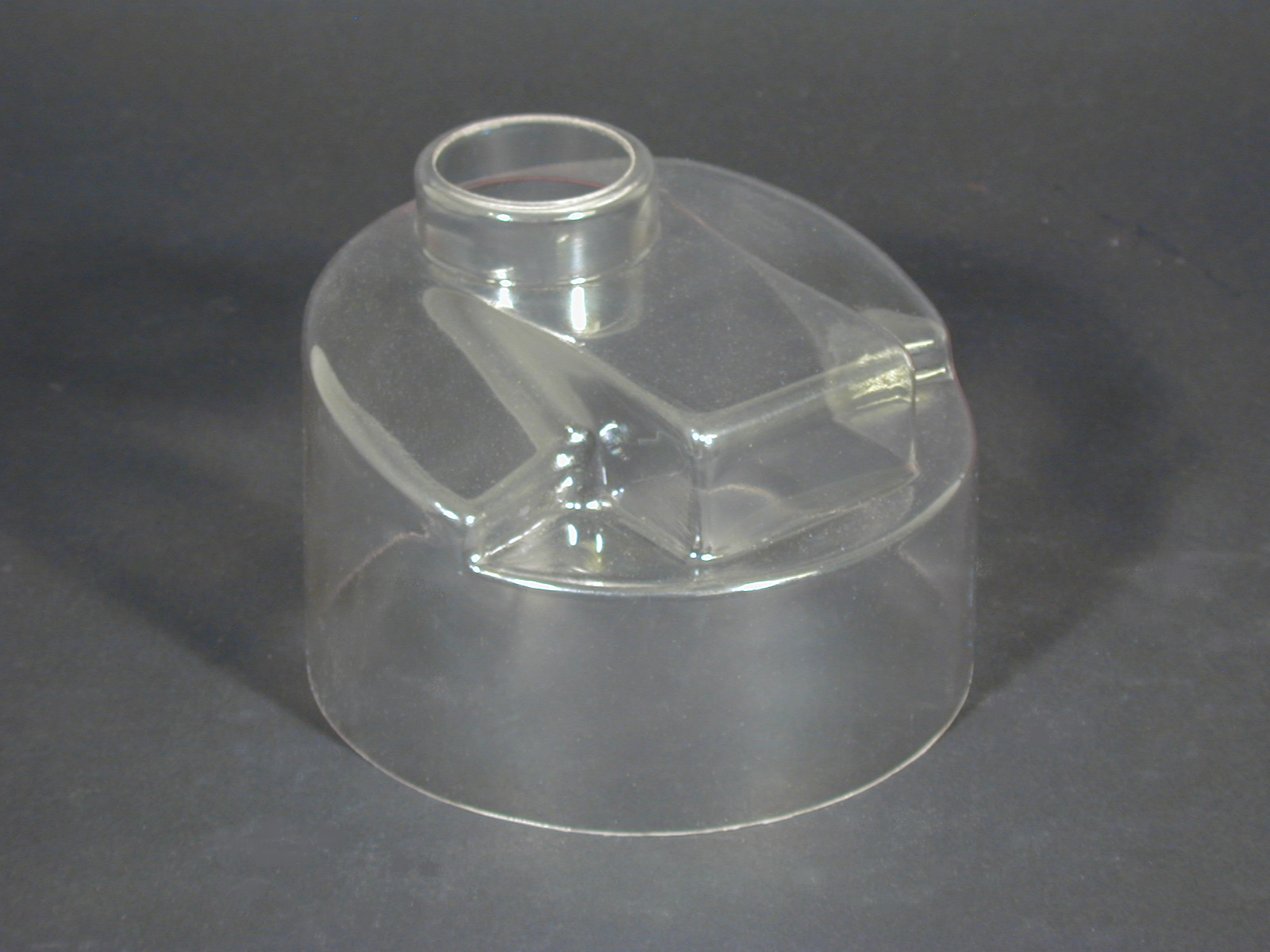

Plastic injection molding is quite similar to plastic extrusion. In fact, plastic extrusion is considered a subtype of injection molding. During this process, manufacturers melt plastic pellets in a hopper, then inject them into two hollow cavities. These hollow cavities are then clamped together and held there under pressure. This helps join the molten plastic. Then, manufacturers allow the plastic shape to cool and harden. Once it’s solid, they separate the two halves of the mold and eject the new plastic part. Plastic injection molding is useful when you want to create tight tolerances. It is also great for high volume runs.

Benefits

Plastic extrusion is extremely popular, and for good reason. Its many benefits include: versatility, flexibility (both literally and figuratively), efficiency, affordability and formability. What’s more, the plastic extrusion process creates very little waste. This is because any leftover plastic can simply be gathered up, melted down and used again. Also, because plastic extrusions remain hot for a while after removal from the extrusion machine, manufacturers can make post-extrusion changes.

Things to Consider

If you’re considering a plastic extrusion, you need the assistance of a quality manufacturer. More than that, you need the assistance of the right quality manufacturer. The right manufacturer is one will meet all your needs, including your delivery preferences, delivery timeline, budget and custom requests. To help you on your way, we’ve provided you with the profiles of several industry leading plastic extrusion companies. Check them out to find the right one for you.

Check out our Plastic Tubing website

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services